Industry Insights

Expert guides on drinkware manufacturing, procurement strategies, and market trends for B2B buyers.

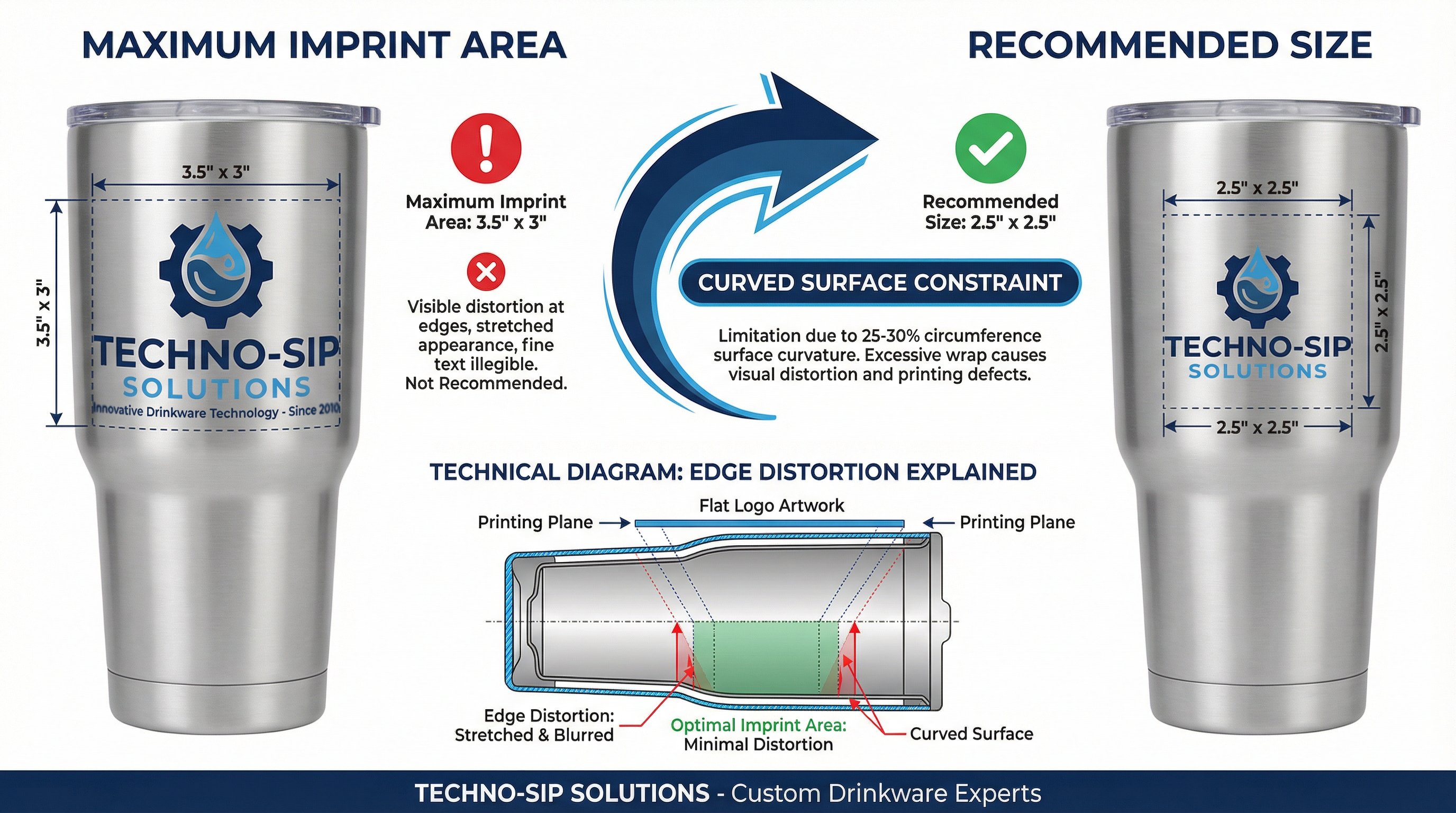

Why buyers who specify maximum imprint area dimensions discover their logo appears distorted and fine text becomes illegible on delivered custom drinkware. How the 25-30% circumference limitation and curved surface physics create predictable quality failures when decoration specifications ignore recommended sizing guidelines—and why the distinction between equipment capability and quality optimization determines whether corporate branding enhances or undermines professional image.

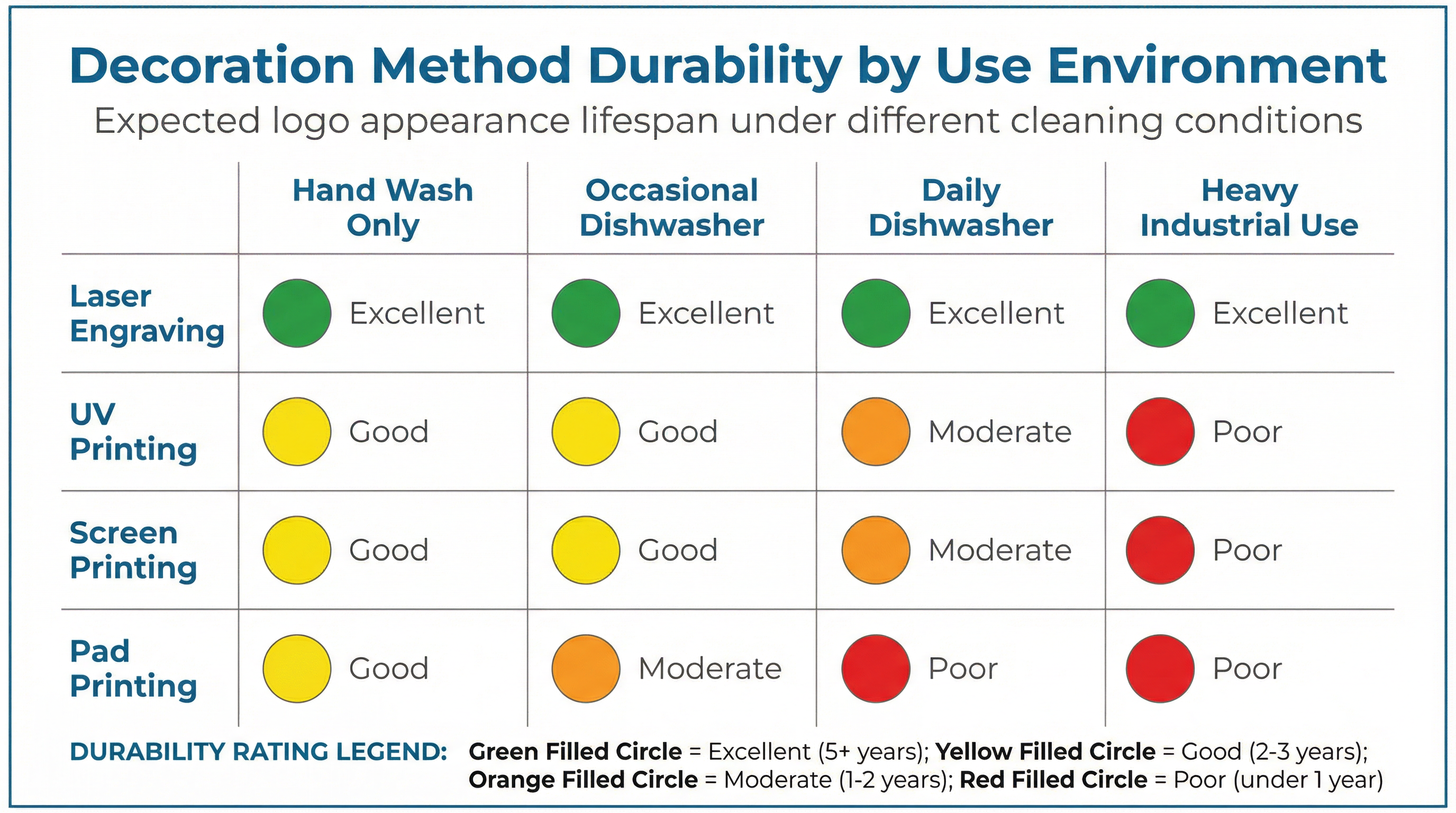

Why buyers who select decoration methods based on visual appeal discover premature logo degradation after six months of daily use. How the distinction between design decisions and durability specifications determines whether UV-printed tumblers maintain brand presentation—and why use environment specification during the selection phase prevents the predictable disappointment of faded logos on products destined for heavy dishwasher exposure.

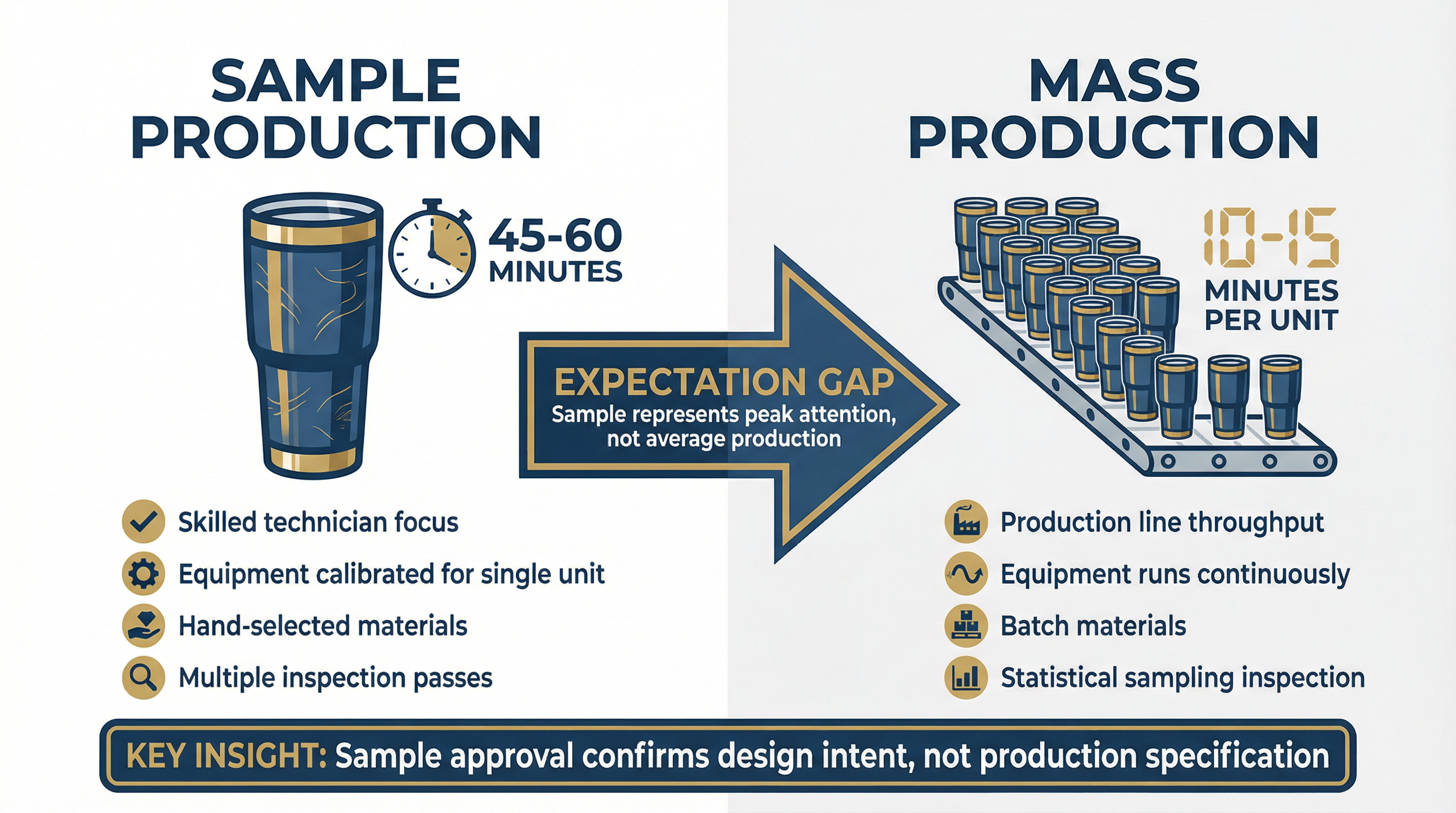

Why buyers who approve a perfect sample discover 2-3% of production units exhibit minor variations in logo position, color saturation, or surface finish. How the fundamental difference between sample-level attention (45-60 minutes per unit) and production-line throughput (10-15 minutes per unit) creates predictable quality gaps—and why treating sample approval as design confirmation rather than production specification prevents $3,000-8,000 rework disputes.

Why buyers who specify identical Pantone codes for multi-product drinkware orders receive visually inconsistent results. How substrate reflectivity, porosity, and base color interact with decoration methods to shift perceived color by 10-25%—and why glossy ceramic, matte stainless steel, and powder-coated bottles interpret the same Pantone reference differently due to materials physics rather than supplier quality control.

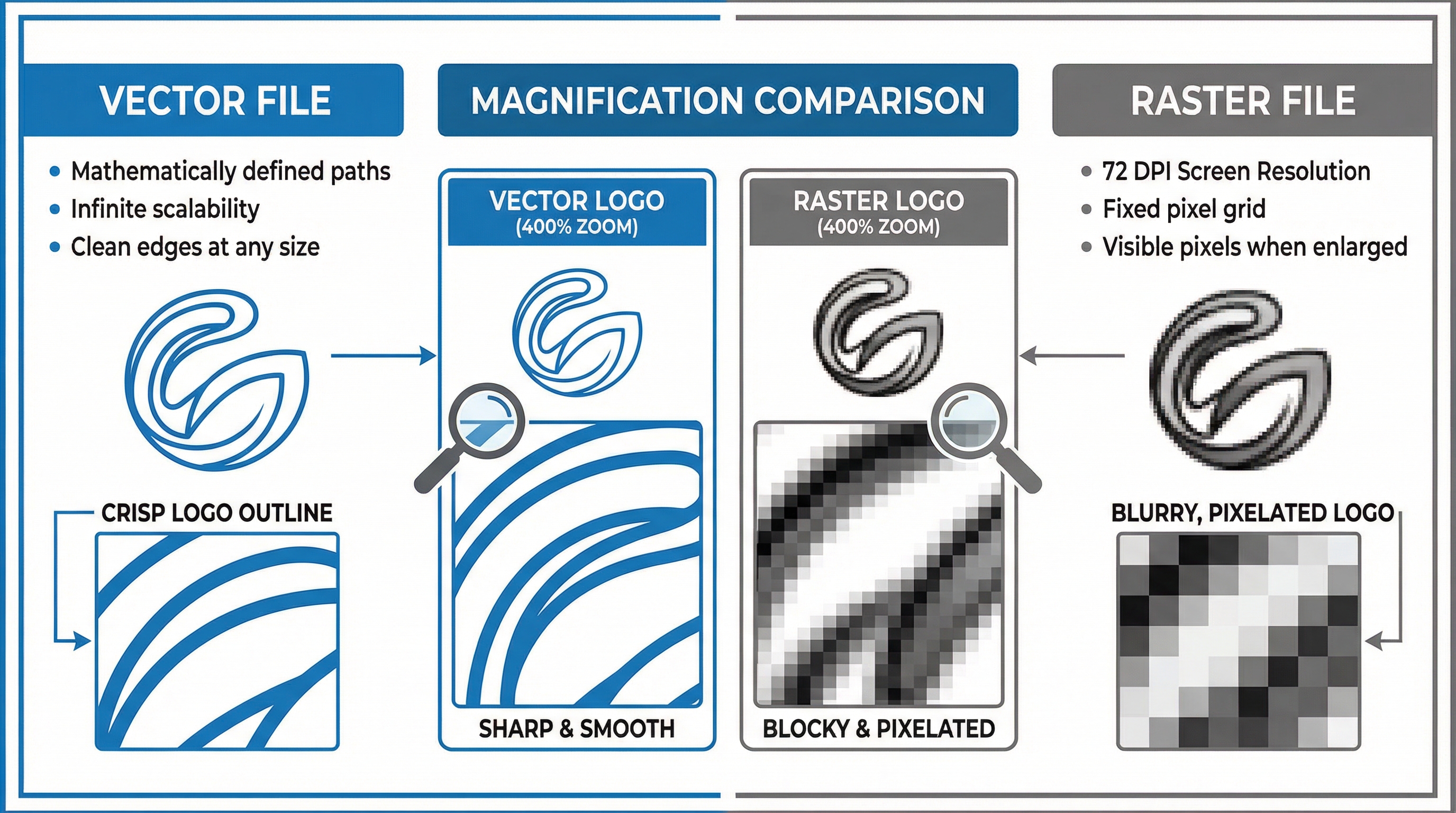

Why artwork that looks crisp on a 27-inch monitor fails prepress review for custom tumbler production. How the fundamental difference between 72 DPI screen resolution and 300 DPI print requirements creates a predictable 3-5 day delay cycle—and why re-saving a JPG as AI does not transform pixels into scalable vector paths. The decoration method dependency that determines whether your file is production-ready or requires costly conversion.

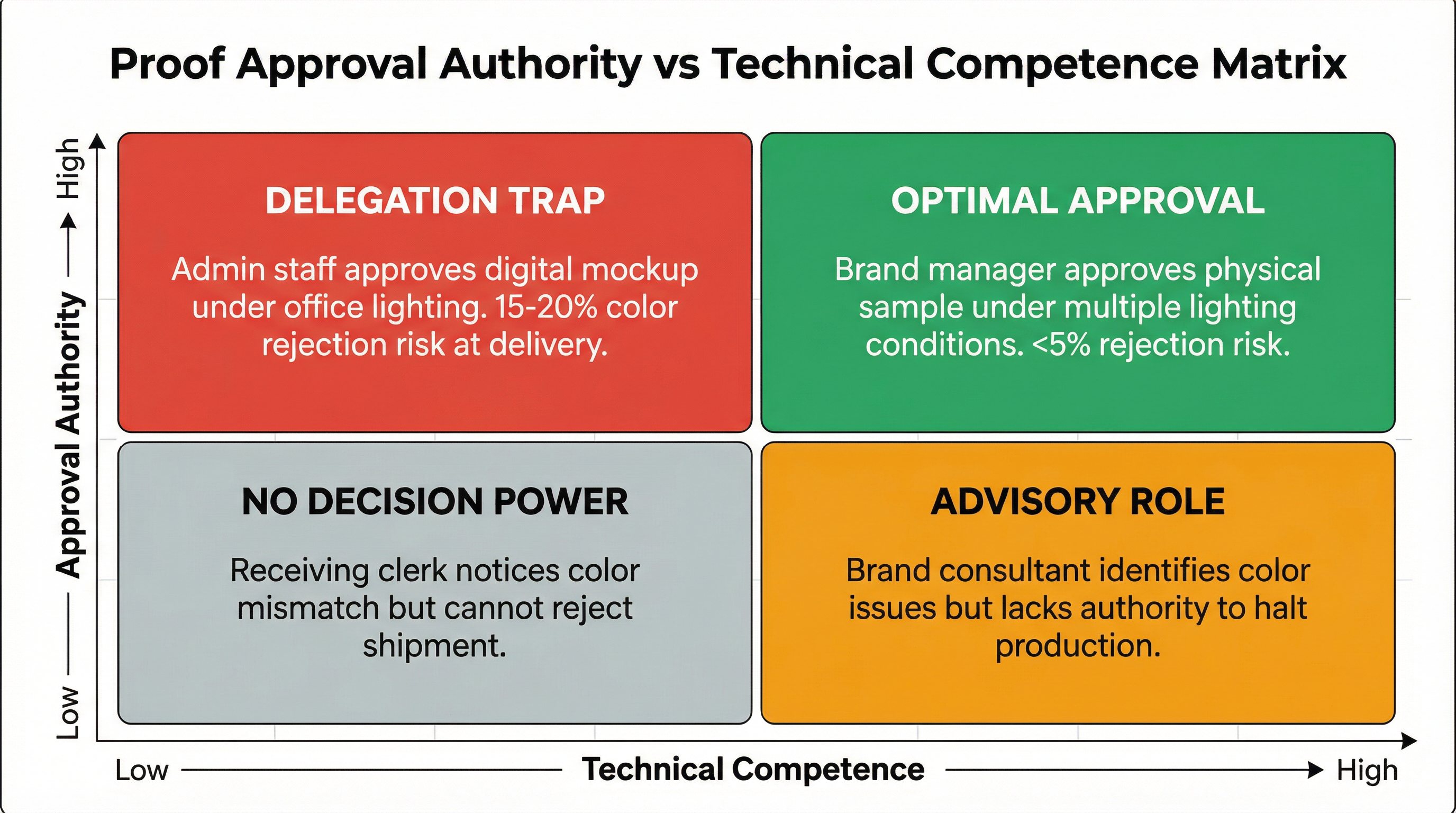

Why buyers who delegate proof approval to administrative staff without cross-functional review discover 15-20% color perception shifts at delivery, despite approved digital mockups viewed under office fluorescent lighting. How the mismatch between approval authority and technical competence creates production commitments based on incomplete evaluation—and why physical sample approval under multiple lighting conditions is the only reliable validation method.

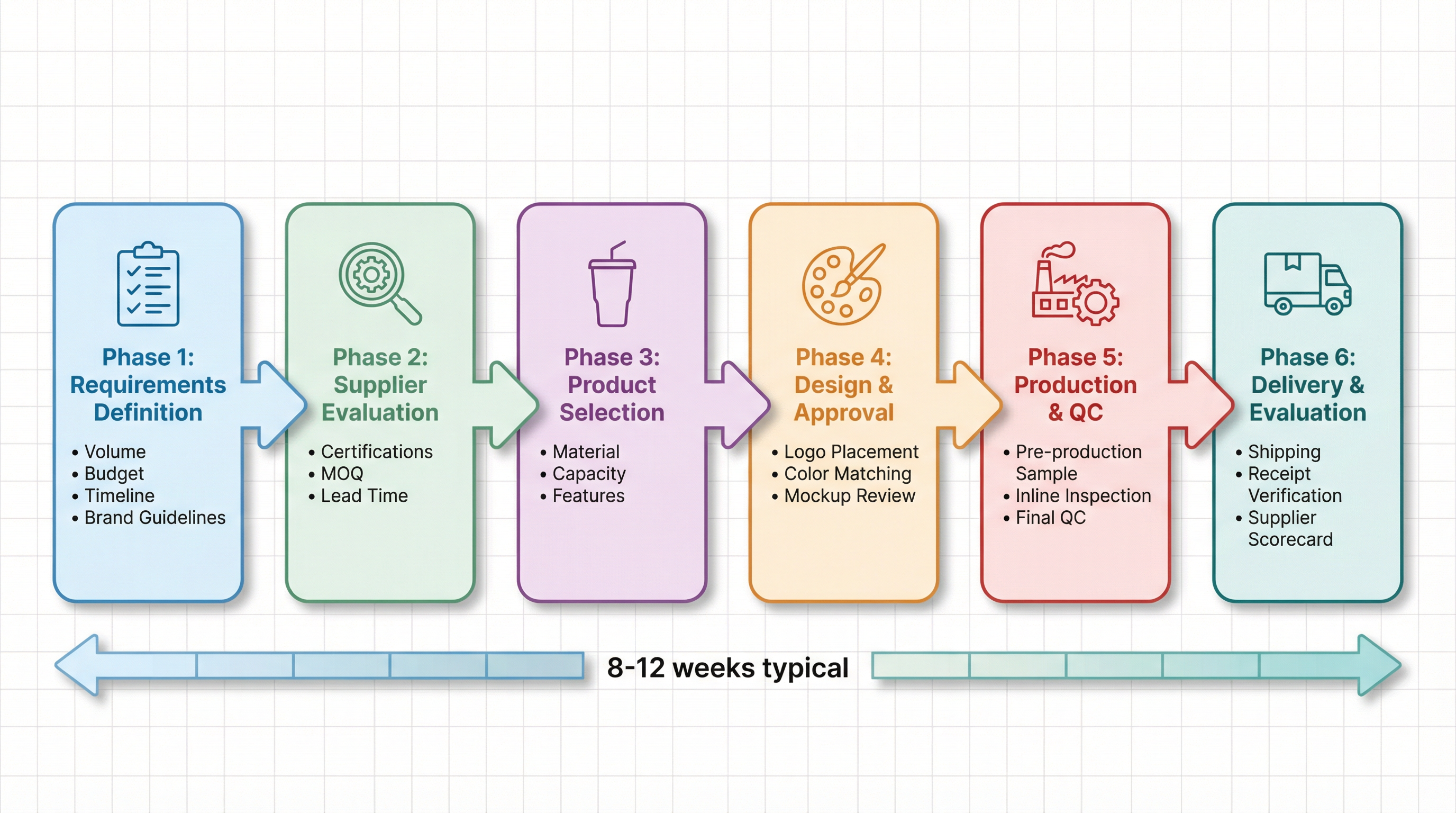

Master the complete customization process for corporate drinkware orders—from supplier compliance verification to production approval. Includes FDA regulations, Pantone color matching, decoration method trade-offs, and enterprise procurement strategies for U.S. buyers.

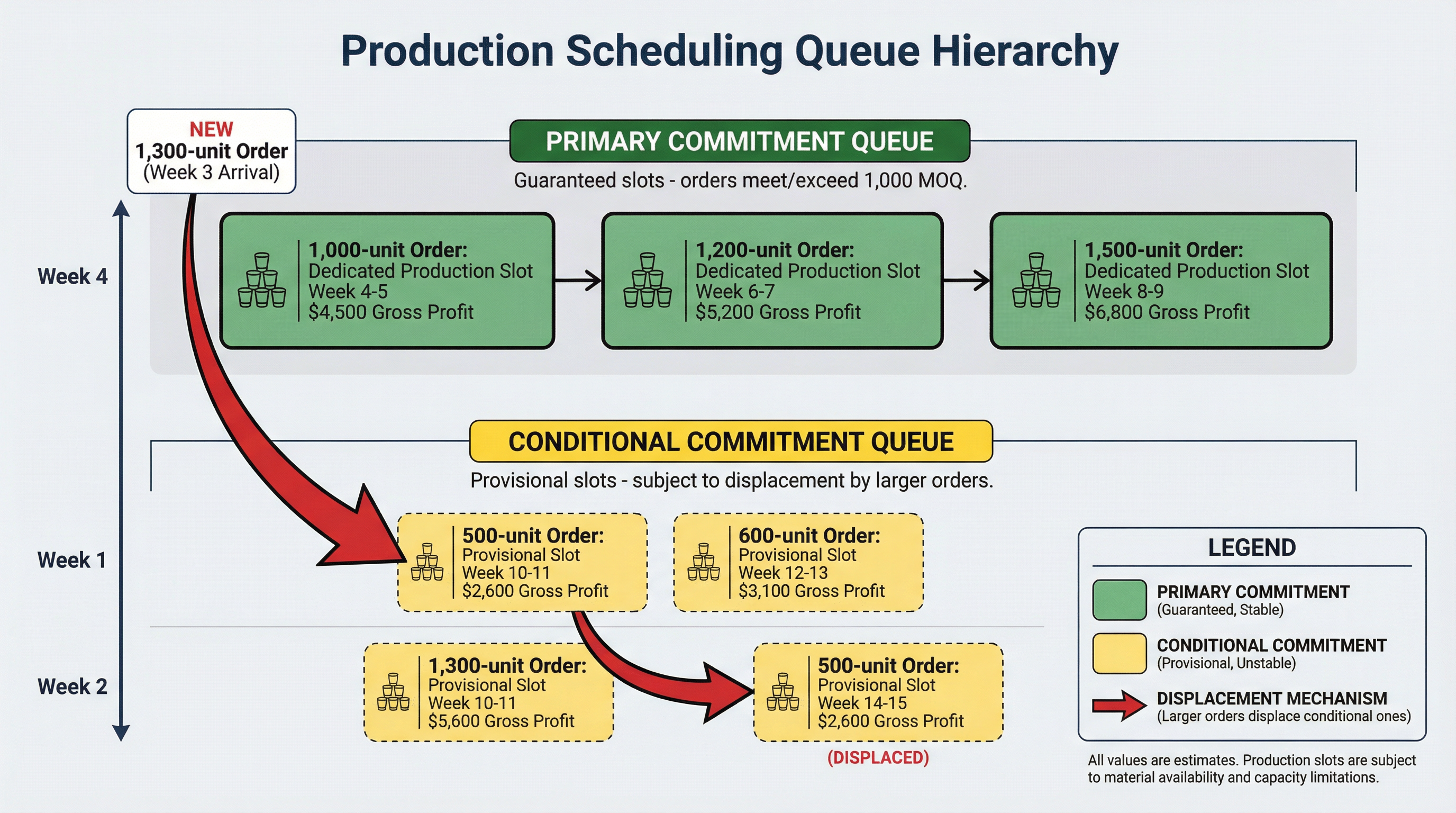

Why buyers who order 500 custom tumblers below the 1,000-unit MOQ—paying a 27% premium for flexibility—discover their 8-week lead time becomes 12-14 weeks when larger orders arrive and displace their production slot. How factories categorize below-MOQ orders as 'conditional commitments' in a standby queue rather than guaranteed production slots, and why the premium compensates for production inefficiency but does not purchase timeline certainty.

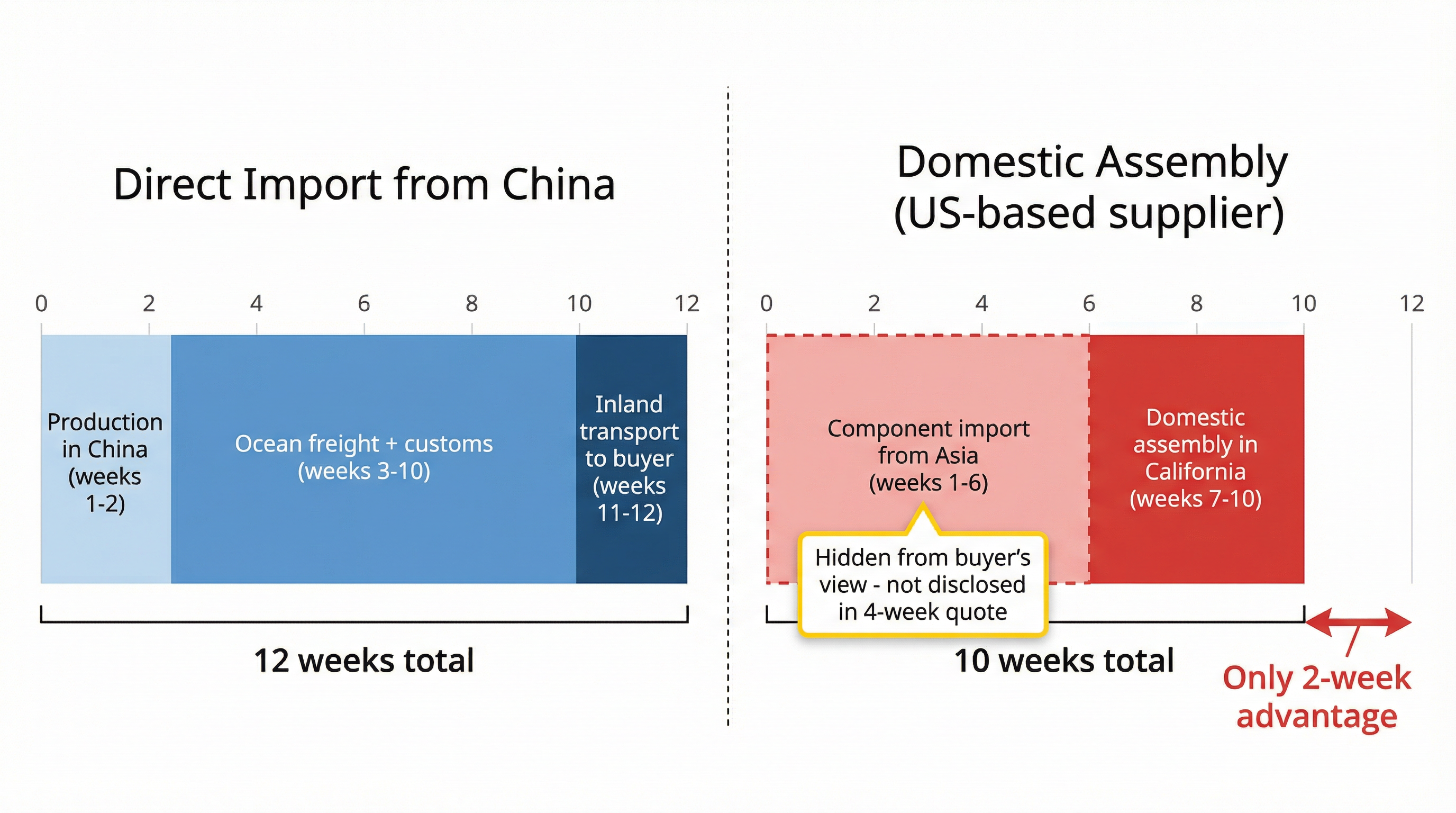

Why buyers who select domestic suppliers expecting 4-week lead times discover 10-week realities when 70% of components are imported from Asia. How the distinction between assembly location and component origin creates a hidden 6-week procurement phase that suppliers don't disclose in quotes—and why 'Assembled in USA' is a location statement, not a timeline statement.

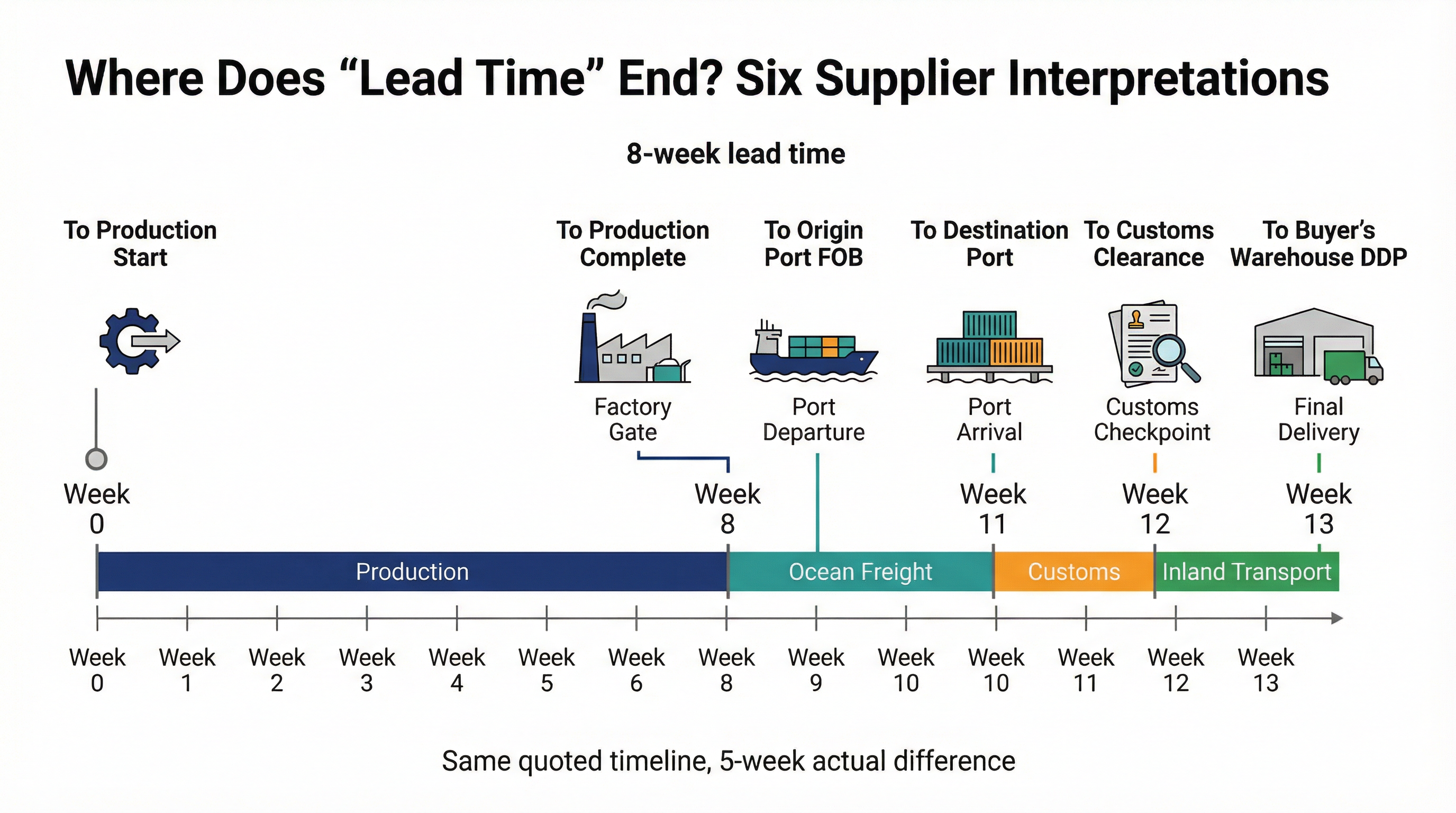

Why buyers who receive '8-week lead time' quotes discover 3-5 week delivery gaps when suppliers define lead time as production completion (excluding ocean freight, customs clearance, and inland transport) while buyers assume it means delivery to their warehouse. How the absence of standardized lead time terminology creates coordination failures across the custom drinkware supply chain—and why clarifying whether quotes end at factory gate, origin port, destination port, or final delivery is the difference between meeting deadlines and operational scrambles.

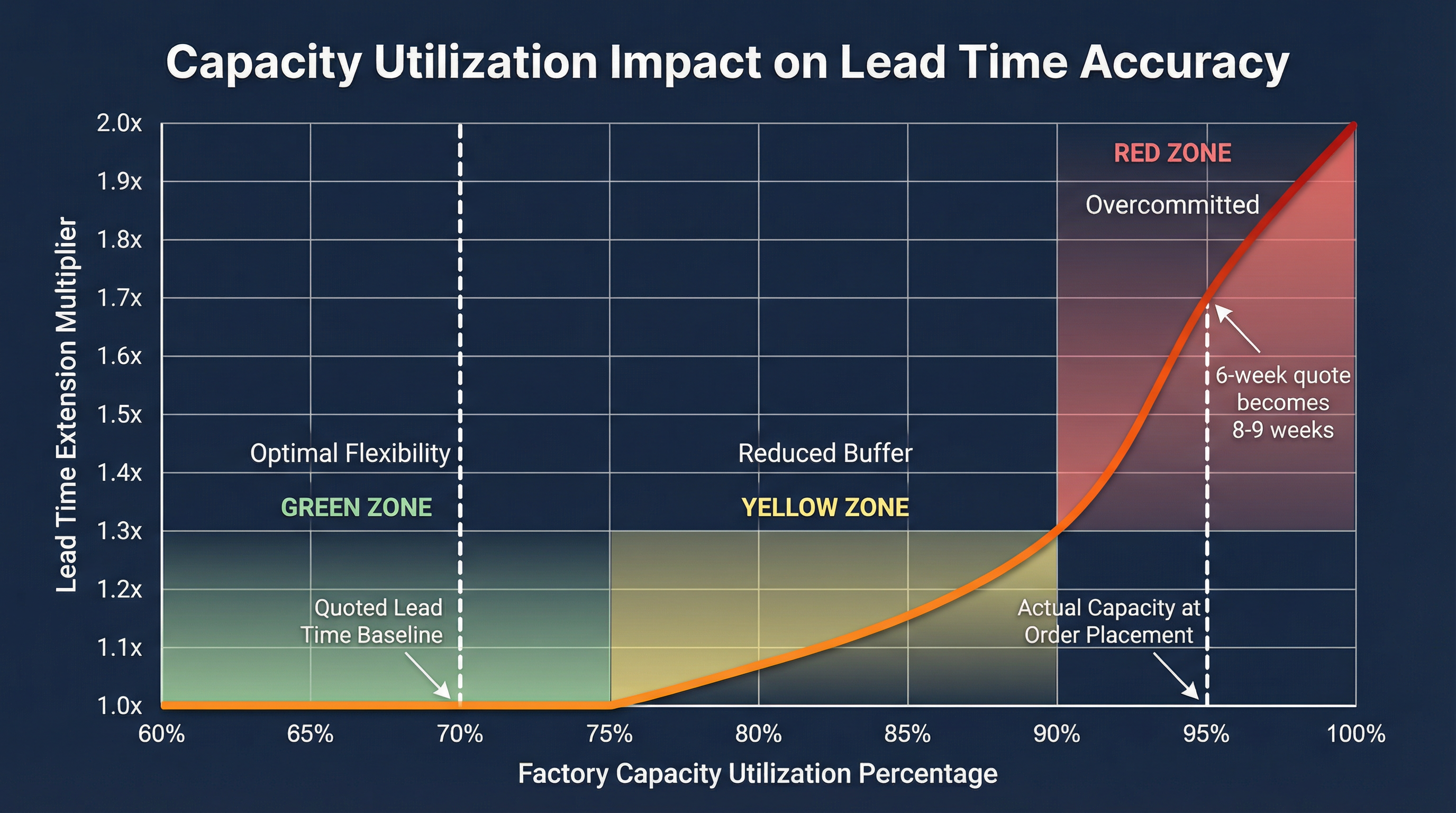

Why buyers who receive 6-week lead time quotes in September discover 8-9 week realities when ordering in October. How suppliers quote based on 70% capacity utilization at inquiry but operate at 95% capacity at order placement—and why treating lead time quotes as static commitments rather than dynamic forecasts guarantees delivery disappointments.

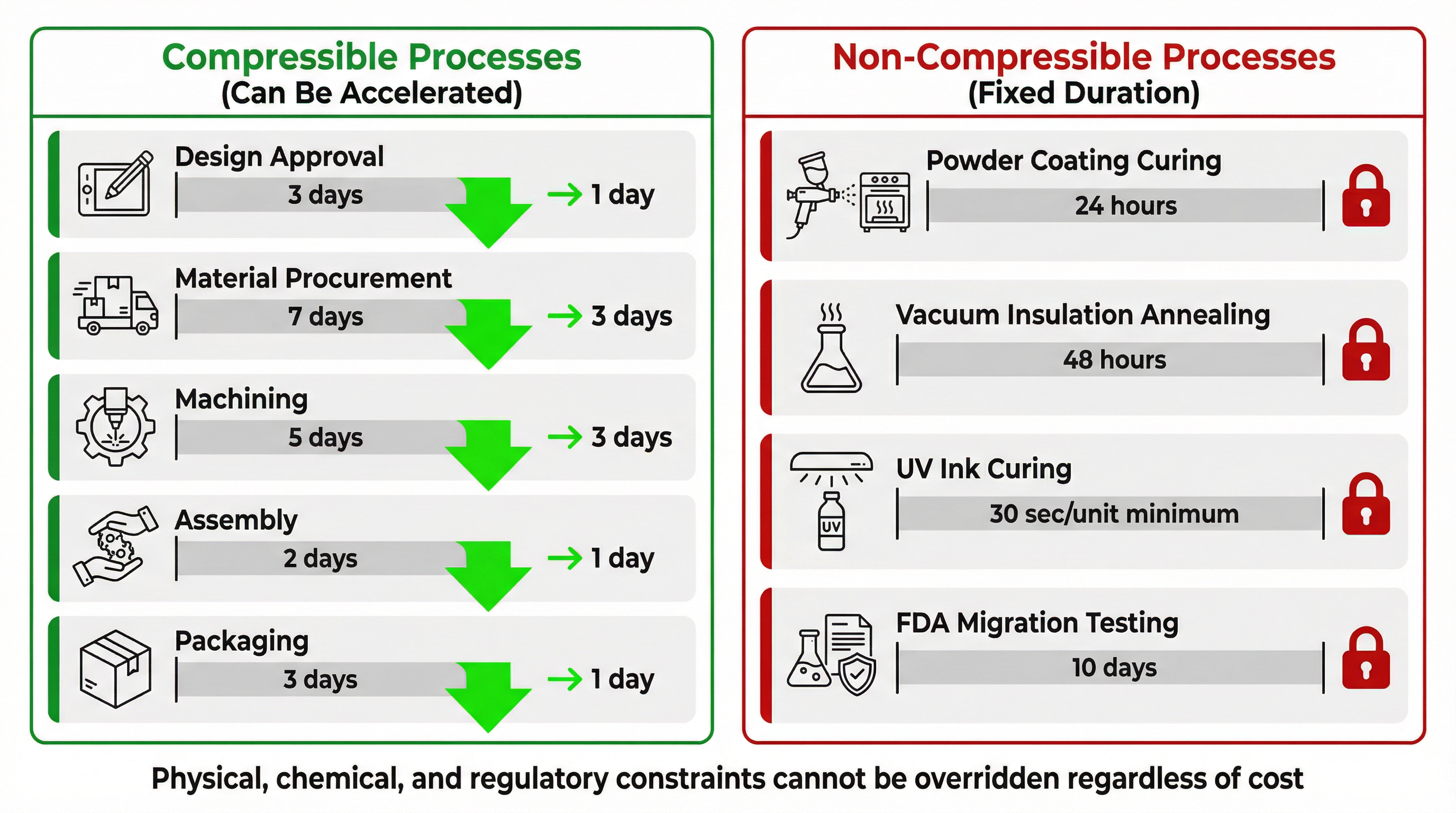

Why buyers who offer 50% rush premiums discover that powder coating still requires 24-hour curing, vacuum insulation still demands 48-hour annealing, and FDA testing still consumes 10 business days. The distinction between compressible processes (design, machining, assembly) and non-compressible processes (curing, cooling, testing) that determines whether rush orders are feasible—and why 40% of manufacturing lead time cannot be accelerated regardless of cost.