The inquiry came in September. The supplier's response was immediate: "6-week lead time for your 2,000-unit custom tumbler order, guaranteed." The buyer, a corporate gifting coordinator for a Fortune 500 tech company, felt confident. The timeline aligned perfectly with their November 15th event. They spent three weeks finalizing design approvals, securing internal budget sign-offs, and coordinating with their marketing team. On October 8th, they submitted the purchase order, expecting delivery by November 19th—exactly six weeks later. On November 12th, one week before their event, the supplier sent an apologetic email: "Production delayed. New delivery date: December 3rd." The buyer's event went forward with generic, off-the-shelf drinkware purchased at retail markup. The supplier's explanation was technically accurate but practically useless: "Our capacity situation changed since your initial inquiry."

This scenario repeats across thousands of corporate procurement decisions annually, not because suppliers intentionally deceive, but because buyers fundamentally misunderstand what a "lead time quote" represents. In practice, this is often where understanding production timelines starts to be misjudged—not as a failure of supplier honesty, but as a failure of buyer verification. The gap between inquiry and order placement creates a capacity verification blind spot that most procurement professionals never learn to see until it costs them a critical delivery.

The core issue is deceptively simple: suppliers quote lead times based on their capacity utilization at the moment of inquiry, not at the moment of order placement. When a drinkware manufacturer tells you "6 weeks" in September, they are calculating based on their current production schedule, which might show 70% capacity utilization with available machine time, manageable material lead times, and predictable labor allocation. This is not a lie. It is a snapshot. But between September inquiry and October order placement, that same manufacturer may have accepted three other orders, pushing their capacity utilization to 92%. The 6-week lead time that was accurate in September becomes an 8-week reality in October, but the buyer never receives an updated quote because they never asked the right question: "What is your current capacity utilization, and how will it change by the time I place my order?"

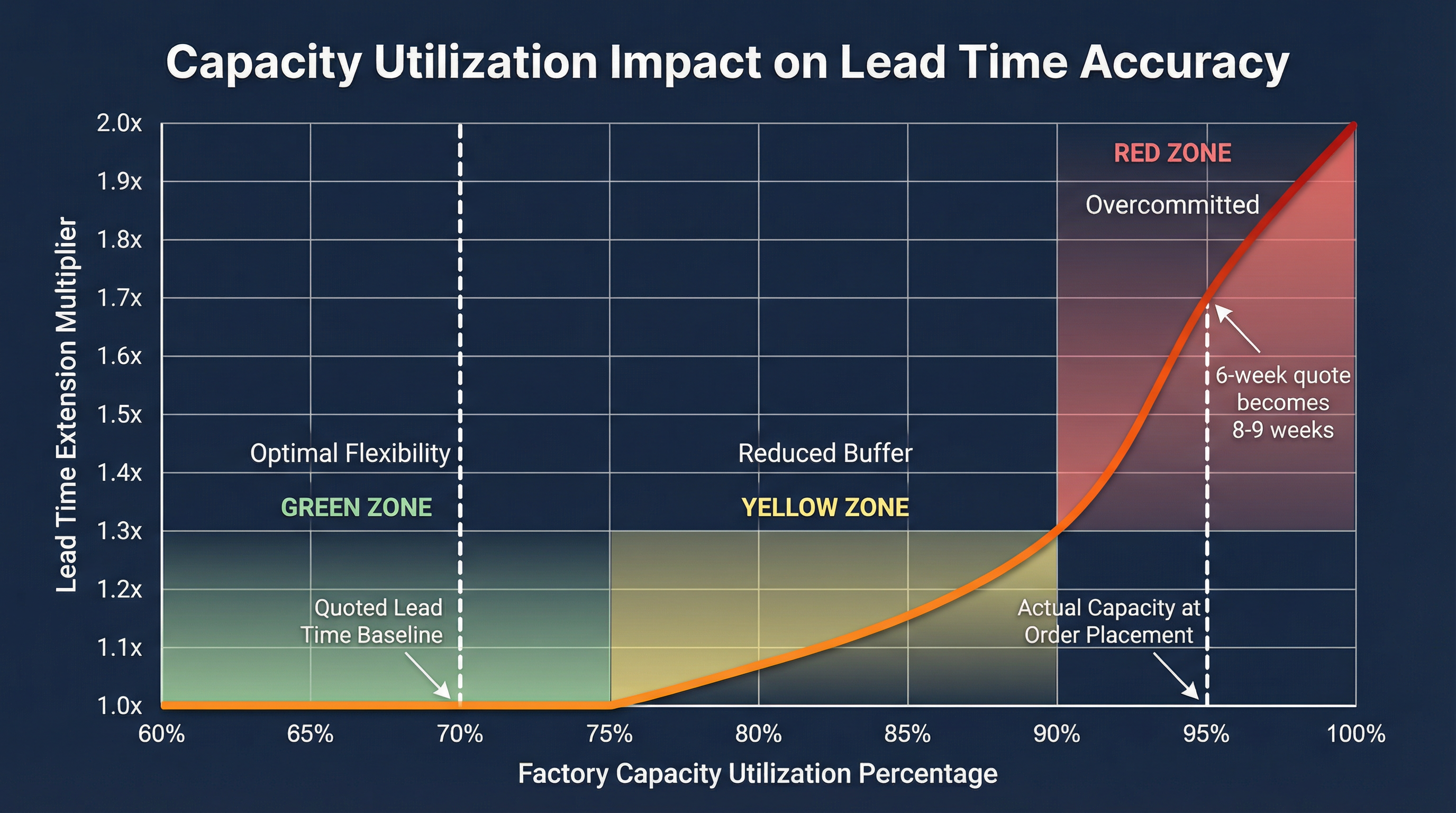

The distinction between quoted lead time and achievable lead time becomes critical when you understand how manufacturing capacity functions. Production facilities do not operate at 100% capacity by design.

Industry best practice targets 70-85% capacity utilization because this range provides flexibility for equipment maintenance, material delays, quality issues, and unexpected rush orders. When a factory operates at 70% capacity, they can absorb a new order without extending lead times because they have available machine hours, labor bandwidth, and scheduling flexibility. At 85% capacity, they can still accommodate new orders but with tighter margins—any material delay or equipment breakdown immediately impacts delivery dates. At 95% capacity, they are effectively overcommitted. Every new order extends lead times because there is no buffer for variability. The problem is that suppliers rarely disclose their current capacity utilization during the inquiry phase, and buyers rarely ask.

Industry best practice targets 70-85% capacity utilization because this range provides flexibility for equipment maintenance, material delays, quality issues, and unexpected rush orders. When a factory operates at 70% capacity, they can absorb a new order without extending lead times because they have available machine hours, labor bandwidth, and scheduling flexibility. At 85% capacity, they can still accommodate new orders but with tighter margins—any material delay or equipment breakdown immediately impacts delivery dates. At 95% capacity, they are effectively overcommitted. Every new order extends lead times because there is no buffer for variability. The problem is that suppliers rarely disclose their current capacity utilization during the inquiry phase, and buyers rarely ask.

This creates what I call the "capacity verification illusion"—the belief that a supplier's lead time quote is a commitment rather than an estimate based on assumptions. Buyers treat the quoted lead time as a fixed contract term, when in reality it is a conditional forecast that assumes the supplier's capacity situation remains stable between inquiry and order. This assumption breaks down most frequently in three scenarios: seasonal capacity shifts, competitive order timing, and material supply chain disruptions. In the seasonal scenario, a buyer inquires in August when the factory is at 65% capacity, then places their order in September when the factory has accepted multiple Q4 holiday orders and is now at 90% capacity. The lead time that was accurate in August is obsolete by September, but the buyer never receives notification because they never established a verification protocol.

The competitive order timing scenario is even more insidious because it involves factors completely outside the buyer's visibility. When you inquire about lead times in early September, you are not the only buyer making that inquiry. Your supplier is simultaneously quoting to five other potential clients, all with similar timelines and order sizes. If three of those clients place orders before you do, the supplier's capacity situation has fundamentally changed by the time your purchase order arrives. The lead time they quoted to you in good faith is no longer achievable, but they may accept your order anyway, hoping to manage the capacity constraint through overtime, subcontracting, or schedule optimization. This is not malicious—it is optimistic. But optimism does not deliver products on time.

Material supply chain disruptions represent the third major verification blind spot. When a supplier quotes you a 6-week lead time, they are assuming their material suppliers will deliver stainless steel tubes in 10 days, powder coating materials in 5 days, and packaging components in 7 days. These assumptions are based on historical averages, not current commitments. If their steel supplier's lead time has recently extended from 10 days to 18 days due to increased demand from other industries, your supplier's 6-week quote is immediately inaccurate by 8 days. But most suppliers do not re-verify material lead times before quoting to buyers—they rely on historical data that may be weeks or months out of date. This means the lead time you receive is based on outdated assumptions about upstream supply chain performance.

The verification challenge is compounded by the fact that most buyers lack the expertise to ask capacity-validating questions during the inquiry phase. When a buyer asks, "What is your lead time for 2,000 custom tumblers with laser engraving?" the supplier answers with a number: "6 weeks." The buyer writes down "6 weeks" and moves forward. What the buyer should ask is: "What is your current capacity utilization? How many orders are currently in your production queue? What is your lead time for this order if I place it today versus if I place it in three weeks? What material lead times are you assuming in your quote? How often do you re-verify those material lead times?" These questions force the supplier to move from generic estimates to specific commitments based on current conditions.

The capacity utilization question is particularly revealing because it exposes whether the supplier operates with transparency or opacity. A supplier who can immediately tell you, "We are currently at 78% capacity with 12 active orders in production and 4 orders in pre-production material procurement" is demonstrating systematic capacity management. A supplier who responds with vague statements like "We have capacity available" or "We can handle your order" is either hiding capacity constraints or lacks the systems to track capacity accurately. Both scenarios are red flags. The transparent supplier may tell you that your order will take 7 weeks instead of 6 because they are already committed to other clients, but this honesty allows you to make an informed decision. The opaque supplier will tell you 6 weeks, accept your order, and deliver in 9 weeks because they never had accurate capacity data in the first place.

The production queue question reveals how many orders are competing for the same resources your order will require. If a supplier has 12 orders in production and your order requires the same powder coating line, laser engraving equipment, and assembly labor as 8 of those 12 orders, you are effectively in a queue. Your lead time is not just the time required to produce your order—it is the time required to produce your order plus the time required to complete the orders ahead of you in the queue. Suppliers who operate with transparent scheduling systems can show you exactly where your order will fit in the production sequence. Suppliers who lack these systems will give you an optimistic estimate that assumes perfect scheduling efficiency and zero delays from preceding orders.

The timing sensitivity question—"What is your lead time if I place this order today versus three weeks from now?"—forces the supplier to acknowledge that lead times are dynamic, not static. A supplier who can differentiate between these scenarios is demonstrating that they actively manage their capacity and update their lead time quotes based on current conditions. A supplier who gives you the same lead time regardless of order timing is either operating with significant excess capacity (unlikely in a competitive market) or is not actively managing their production schedule (a major risk indicator). The honest answer might be: "If you order today, we can deliver in 6 weeks. If you order in three weeks, we will likely be at higher capacity due to other orders we expect to receive, so delivery would be 7-8 weeks." This transparency allows you to make strategic decisions about order timing.

The material lead time assumption question is critical because it exposes whether the supplier has recently verified their upstream supply chain or is relying on outdated data. When you ask, "What material lead times are you assuming in your 6-week quote?" a well-managed supplier will respond with specific, recently verified data: "We are assuming 12 days for 304 stainless steel tubes from our primary supplier, verified as of last week. We are assuming 5 days for powder coating materials from our coating supplier, verified yesterday. We are assuming 7 days for packaging materials from our packaging supplier, verified three days ago." This level of specificity indicates that the supplier actively manages their supply chain and updates their lead time quotes based on current supplier performance. A supplier who responds with generic statements like "We assume normal material lead times" is signaling that they have not recently verified their assumptions and may be quoting based on outdated data.

The re-verification frequency question—"How often do you re-verify material lead times?"—reveals whether the supplier operates proactively or reactively. A supplier who re-verifies material lead times weekly or bi-weekly is actively managing supply chain risk and can detect changes in upstream lead times before they impact customer deliveries. A supplier who re-verifies material lead times monthly or quarterly is operating reactively and will only discover supply chain delays after they have already accepted orders based on outdated assumptions. This reactive approach guarantees that some percentage of their lead time quotes will be inaccurate, and buyers who place orders based on those quotes will experience delays.

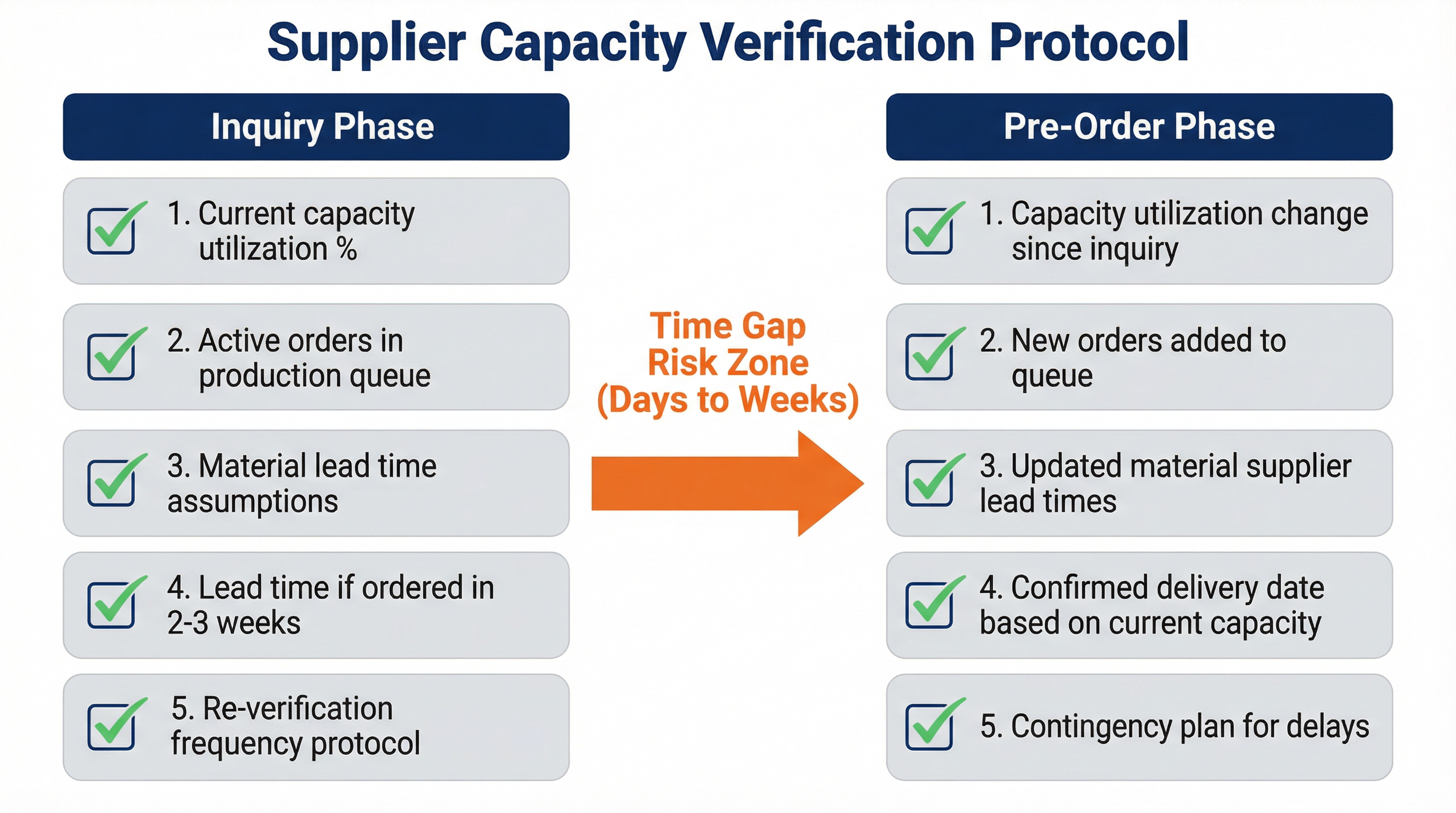

The practical implication of these verification blind spots is that buyers must shift from passive acceptance of lead time quotes to active validation of capacity claims. This validation process should occur at two critical moments: during the initial inquiry phase and immediately before placing the purchase order.

During the initial inquiry phase, buyers should request not just a lead time quote but also the capacity utilization data, production queue status, and material lead time assumptions that underpin that quote. This establishes a baseline understanding of whether the quoted lead time is achievable under current conditions. Immediately before placing the purchase order—which may be days or weeks after the initial inquiry—buyers should re-verify that the supplier's capacity situation has not materially changed. This re-verification can be as simple as asking: "Has your capacity utilization changed since our initial discussion? Are there any new orders in your production queue that might impact the lead time you originally quoted?"

During the initial inquiry phase, buyers should request not just a lead time quote but also the capacity utilization data, production queue status, and material lead time assumptions that underpin that quote. This establishes a baseline understanding of whether the quoted lead time is achievable under current conditions. Immediately before placing the purchase order—which may be days or weeks after the initial inquiry—buyers should re-verify that the supplier's capacity situation has not materially changed. This re-verification can be as simple as asking: "Has your capacity utilization changed since our initial discussion? Are there any new orders in your production queue that might impact the lead time you originally quoted?"

Suppliers who operate with transparent capacity management systems will welcome these questions because they demonstrate that the buyer understands manufacturing realities and is seeking a partnership based on accurate information rather than optimistic promises. Suppliers who resist these questions or provide vague, non-specific answers are signaling that they either lack the systems to track capacity accurately or are unwilling to share information that might reveal capacity constraints. In either case, the buyer should treat this resistance as a risk indicator and consider alternative suppliers who demonstrate greater transparency.

The capacity verification challenge is not about catching suppliers in lies—it is about recognizing that lead time quotes are conditional forecasts based on assumptions that may change between inquiry and order placement. Buyers who treat lead time quotes as fixed commitments are setting themselves up for disappointment. Buyers who actively verify capacity claims, validate material lead time assumptions, and re-confirm lead times immediately before placing orders are dramatically reducing their risk of delivery delays. The difference between these two approaches is not just operational competence—it is the difference between receiving products on time and scrambling to explain to stakeholders why critical deliveries are weeks late.

The verification process requires discipline and a willingness to ask uncomfortable questions that some suppliers may perceive as intrusive or distrustful. But professional suppliers who operate with systematic capacity management will recognize these questions as indicators of a sophisticated buyer who understands manufacturing realities. These suppliers will respond with detailed, data-driven answers that build confidence in their ability to deliver on their commitments. Suppliers who respond defensively or evasively to capacity verification questions are revealing that they lack the systems or transparency required for reliable delivery performance. In the high-stakes environment of corporate procurement, where delivery delays can cascade into event cancellations, revenue losses, and damaged client relationships, the cost of failing to verify supplier capacity claims far exceeds the discomfort of asking difficult questions during the inquiry phase.