How Long Does It Take to Produce Custom Drinkware? A Complete Lead Time Guide for US Businesses

When corporate procurement teams approach suppliers with requests for custom drinkware orders, the first question is almost always the same: "How long will this take?" The answer, unfortunately, is rarely straightforward. A supplier might respond with "four to six weeks," but that estimate often excludes design revisions, compliance testing, shipping delays, and seasonal capacity constraints. By the time the order arrives—often days or weeks later than expected—the trade show has passed, the product launch has been postponed, or the holiday gifting window has closed. The cost of miscalculating lead time is not just inconvenience; it is missed revenue, damaged relationships, and wasted budget.

Understanding production lead time for custom drinkware requires more than accepting a supplier's initial timeline.

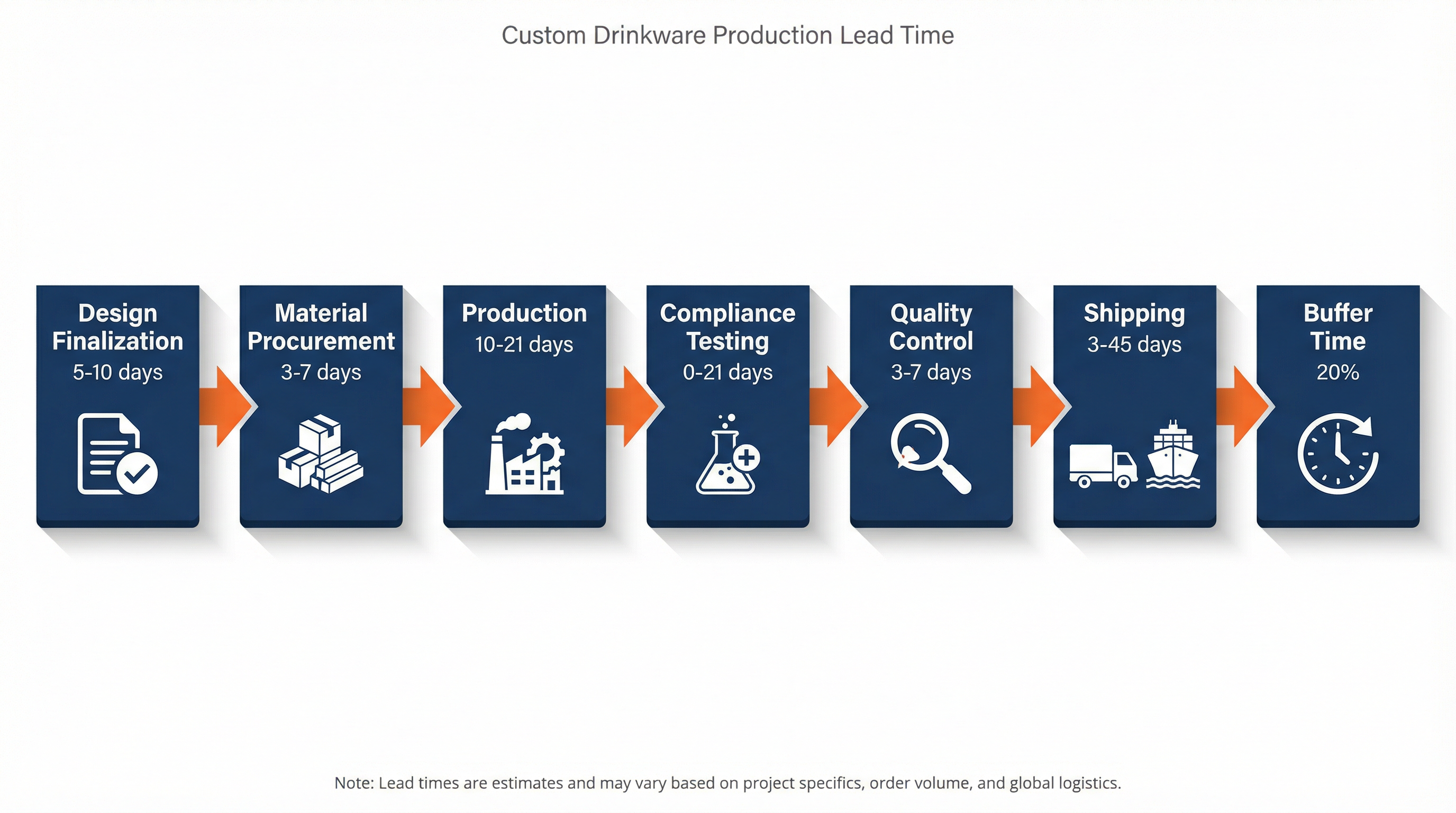

The seven critical phases of custom drinkware production, from design finalization to delivery. Each phase has specific duration ranges that depend on order complexity, material selection, and supplier location. It requires breaking down the entire process into measurable phases, recognizing which variables are within your control, and identifying the hidden factors that extend delivery dates. Lead time is not a single number; it is a calculation that depends on material selection, customization complexity, order volume, supplier location, compliance requirements, and the time of year you place the order. Buyers who treat lead time as a fixed constraint rather than a dynamic variable are systematically underestimating the time required to deliver high-quality custom drinkware, and they are paying for that miscalculation in expedited shipping fees, rushed production surcharges, or compromised product quality.

The seven critical phases of custom drinkware production, from design finalization to delivery. Each phase has specific duration ranges that depend on order complexity, material selection, and supplier location. It requires breaking down the entire process into measurable phases, recognizing which variables are within your control, and identifying the hidden factors that extend delivery dates. Lead time is not a single number; it is a calculation that depends on material selection, customization complexity, order volume, supplier location, compliance requirements, and the time of year you place the order. Buyers who treat lead time as a fixed constraint rather than a dynamic variable are systematically underestimating the time required to deliver high-quality custom drinkware, and they are paying for that miscalculation in expedited shipping fees, rushed production surcharges, or compromised product quality.

Expert Quick Answer: Standard custom drinkware production in the USA typically requires 14 to 21 business days for domestic suppliers and 45 to 60 business days for overseas sourcing, excluding design finalization and shipping. However, this baseline assumes standard materials, single-color laser engraving, moderate order volumes (500-2,000 units), and off-peak ordering periods. Factors such as custom Pantone color matching, multi-color UV printing, FDA compliance testing, peak season capacity constraints (Q4), and complex packaging requirements can extend total lead time to 90 to 120 days. The most reliable approach is to calculate lead time as: Design Finalization (5-10 days) + Production (14-21 days domestic / 30-45 days overseas) + Compliance Testing (0-21 days if required) + Shipping (3-14 days) + Buffer (20% of total). This formula accounts for the variables that suppliers rarely disclose upfront and ensures your custom drinkware arrives when you need it, not when the supplier is ready to ship.

Why Custom Drinkware Lead Time Is a Critical Decision Factor for US Businesses

For enterprise buyers, lead time is not simply a logistical detail—it is a strategic constraint that shapes budget allocation, event planning, and supplier selection. When a company commits to a trade show in September, orders promotional drinkware in July, and receives the shipment in October, the financial impact extends far beyond the cost of the drinkware itself. The booth space has been paid for, the marketing materials have been printed, and the sales team has traveled to the event. The absence of branded giveaways does not just reduce booth traffic; it signals to attendees that the company is disorganized, unreliable, or unprepared. In B2B sales environments where first impressions determine whether a prospect requests a follow-up meeting, the cost of a late drinkware delivery is measured in lost pipeline value, not just the price of the products.

Lead time also determines whether a company can respond to market opportunities or competitive threats. A software startup that secures a last-minute sponsorship at a major industry conference needs custom water bottles within three weeks, not eight. A healthcare organization launching a wellness initiative in January needs insulated tumblers delivered by the first week of the new year, not mid-February. A real estate firm closing a high-value deal wants to present custom drinkware as a closing gift within days, not months. Buyers who cannot accurately predict lead time are forced to either overpay for rush production or miss the opportunity entirely. The ability to compress lead time without sacrificing quality or incurring prohibitive costs is a competitive advantage, and it requires understanding which variables can be controlled and which cannot.

From a budget control perspective, lead time directly impacts total cost of ownership. Buyers who underestimate lead time are forced into rush production, which typically carries a 20% to 40% surcharge on top of standard pricing. They may also need to upgrade from ocean freight to air freight, which can increase shipping costs by 300% to 500%. A 1,000-unit order of stainless steel tumblers that costs $8,500 with standard lead time can balloon to $12,000 or more when rush fees and expedited shipping are added. For companies operating on fixed marketing budgets, these overruns force trade-offs: fewer units, lower-quality materials, or reduced customization. The buyers who manage lead time effectively are the ones who secure the best pricing, the highest quality, and the most reliable delivery, because they are not negotiating from a position of desperation.

The Anatomy of Custom Drinkware Production: What Happens During the Timeline

The production timeline for custom drinkware is not a single continuous process; it is a sequence of discrete phases, each with its own duration, dependencies, and potential delays. Buyers who understand this structure can identify where delays are most likely to occur and take proactive steps to mitigate them. The timeline begins not when the supplier receives the purchase order, but when the buyer finalizes the design and approves the production proof. This distinction is critical, because many buyers assume that production starts immediately after they place the order, when in reality, production cannot begin until the artwork is approved, the payment is received, and the materials are procured.

Design Finalization and Proof Approval (5 to 10 Business Days): This phase is often the most underestimated. Buyers submit a logo file, the supplier prepares a digital proof showing how the logo will appear on the drinkware, and the buyer reviews and approves the proof. In theory, this should take one or two days. In practice, it often takes a week or more, because the initial logo file is not in the correct format (suppliers require vector files such as .AI or .EPS, not .JPG or .PNG), the logo colors do not match the brand guidelines, or the buyer requests revisions after seeing the proof. Each revision cycle adds one to two business days, and if multiple stakeholders need to approve the design—common in large organizations—the approval process can extend to two weeks. Buyers who want to minimize this phase should submit vector artwork in the correct color format (Pantone or CMYK) and consolidate internal approvals before submitting the design to the supplier.

Material Procurement and Production Scheduling (3 to 7 Business Days): Once the design is approved, the supplier must procure the raw materials and schedule the order into the production queue. For standard materials such as 304 stainless steel blanks or stock plastic bottles, this phase is relatively short, because suppliers maintain inventory of commonly used components. However, if the buyer requests a custom Pantone color for powder coating, a non-standard lid type, or a specialty material such as bamboo accents or copper-lined interiors, the supplier must order these components from upstream vendors. Custom powder coating colors typically require a 5 to 7 business day lead time from the coating supplier, and specialty lids or components can take 10 to 14 days if they are not in stock. Buyers who select standard colors and components can reduce this phase to three days; buyers who request custom specifications should expect to add a week or more.

Production and Customization (10 to 21 Business Days): This is the core manufacturing phase, and its duration depends on the material, the customization method, and the order volume. Stainless steel tumblers require more production time than plastic bottles because they involve multiple steps: hydroforming the steel into shape, welding the inner and outer walls, applying vacuum insulation, polishing the surface, applying powder coating, and curing the coating in an oven. Each of these steps has a fixed duration, and they cannot be compressed without compromising quality. Powder coating, for example, requires a 24 to 48 hour curing period at elevated temperatures; rushing this step results in coatings that chip or peel. Ceramic mugs require kiln firing, which adds 2 to 3 days to the timeline. Plastic bottles are faster to produce because they do not require coating or firing, but they still need time for injection molding, cooling, and assembly.

The customization method also affects production time. Laser engraving is the fastest option because it does not require drying or curing; a laser can engrave hundreds of units per hour, and the engraved surface is immediately ready for packaging. UV printing requires a curing period of 12 to 24 hours after printing to ensure the ink adheres properly, which adds a day to the timeline. Screen printing is the slowest method for multi-color designs because each color requires a separate pass through the printer, and each pass must dry before the next color can be applied. A four-color screen print can add 3 to 5 days to the production timeline compared to a single-color laser engraving. Buyers who prioritize speed should choose laser engraving over UV or screen printing, especially for large orders.

Order volume affects production time in non-linear ways. Small orders (200 to 500 units) can often be completed faster than the standard timeline because they can fit into production gaps between larger orders. A supplier with a 2,000-unit order running on the main production line might be able to squeeze a 300-unit order onto a secondary line during downtime. However, very large orders (5,000+ units) may require a dedicated production run, which means the supplier must wait until the production line is available, and the order cannot start until all materials are procured. A 10,000-unit order might take 25 to 30 business days instead of the standard 14 to 18 days, not because the production itself is slower, but because the supplier needs more time to schedule the capacity and procure the materials in bulk.

Quality Control and Packaging (3 to 5 Business Days): After production is complete, the drinkware must be inspected, packaged, and prepared for shipment. Quality control involves visual inspection for defects such as scratches, dents, misaligned logos, or color inconsistencies. Reputable suppliers inspect 100% of units for high-value orders or 10% to 20% of units using AQL (Acceptable Quality Limit) sampling for standard orders. Packaging includes inserting lids, adding silicone gaskets, wrapping each unit in protective sleeves, placing units in individual boxes, and packing boxes into master cartons. For orders with custom packaging—such as branded gift boxes, foam inserts, or retail-ready displays—this phase can extend to 7 to 10 days. Buyers who accept standard packaging can reduce this phase to three days; buyers who require custom packaging should plan for a week.

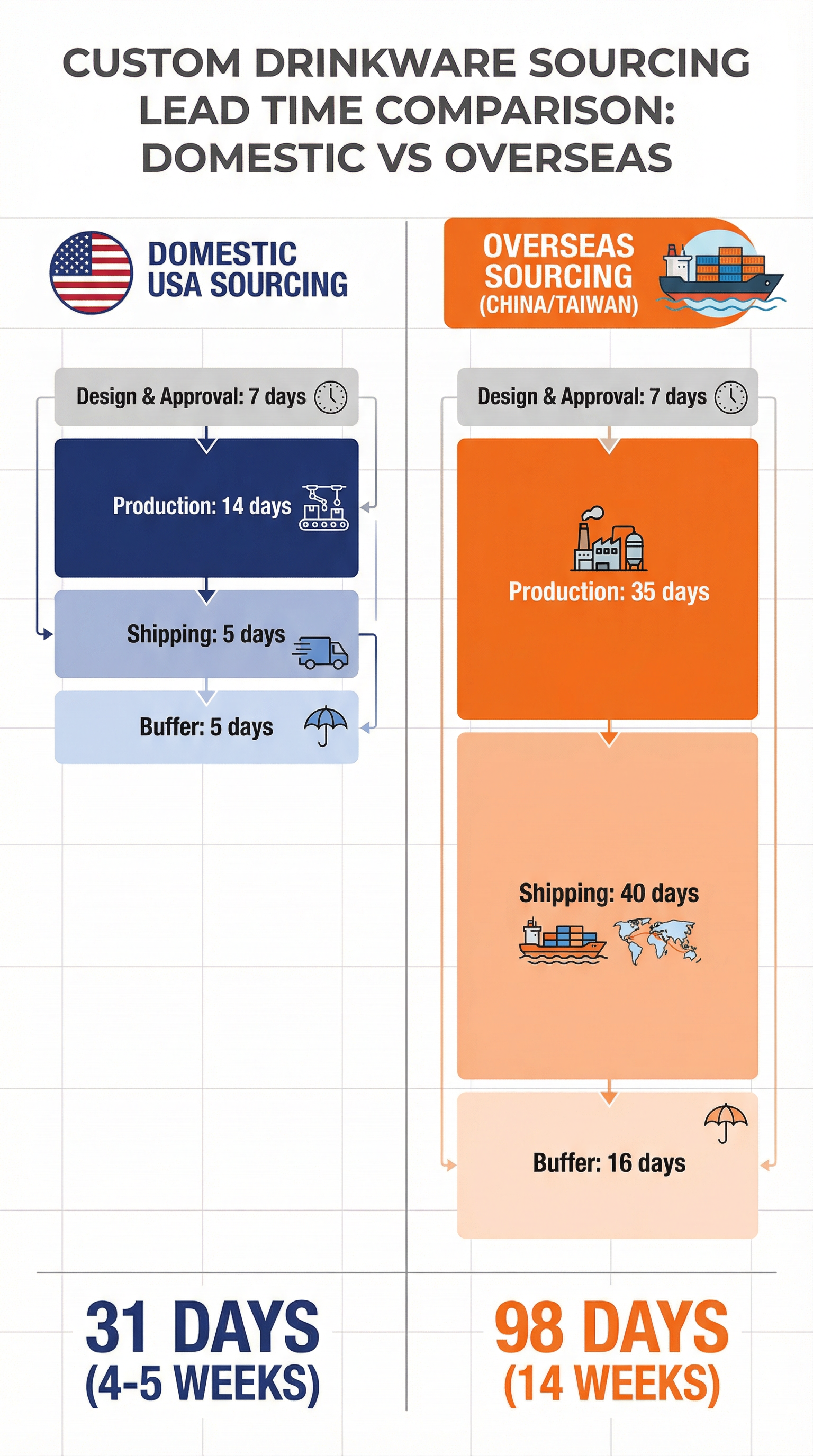

Shipping and Delivery (3 to 14 Business Days Domestic / 30 to 45 Days Overseas): Shipping time depends on the supplier's location and the shipping method. Domestic suppliers in the USA typically ship via UPS, FedEx, or freight carriers, with delivery times ranging from 3 to 7 business days for standard ground shipping and 1 to 3 days for expedited air shipping. Overseas suppliers—primarily located in China, Taiwan, or Vietnam—ship via ocean freight, which takes 30 to 45 days from the port of origin to the destination port, plus an additional 3 to 7 days for customs clearance and inland transportation. Air freight from overseas suppliers reduces shipping time to 7 to 10 days, but it increases shipping costs by 300% to 500%, making it viable only for urgent orders or high-value products. Buyers who source domestically gain a four to six week advantage in total lead time compared to overseas sourcing, which is why many US companies are willing to pay a 15% to 25% premium for domestic production when time is a critical factor.

Side-by-side comparison of total lead time for domestic USA sourcing versus overseas sourcing. The dramatic difference—31 days versus 98 days—demonstrates why lead time is often more important than per-unit cost for time-sensitive orders.

Side-by-side comparison of total lead time for domestic USA sourcing versus overseas sourcing. The dramatic difference—31 days versus 98 days—demonstrates why lead time is often more important than per-unit cost for time-sensitive orders.

How Customization Complexity and Material Selection Affect Lead Time

Not all custom drinkware orders are created equal. A 500-unit order of stainless steel tumblers with single-color laser engraving will have a fundamentally different lead time than a 500-unit order of ceramic mugs with full-color wraparound printing and custom packaging. The variables that extend lead time are not always obvious to buyers, and suppliers do not always disclose them upfront. Understanding which customization choices add time—and how much—allows buyers to make informed trade-offs between design ambition and delivery speed.

Material Type: Stainless steel drinkware typically requires 14 to 18 business days for production because it involves multiple manufacturing steps: forming, welding, vacuum insulation, polishing, and coating. Ceramic mugs require 12 to 16 days due to kiln firing and cooling cycles. Plastic bottles are the fastest option at 10 to 14 days because they do not require coating or firing, but they are also perceived as lower quality, which may not align with brand positioning. Glass drinkware takes 16 to 21 days because it requires careful handling, specialized packaging to prevent breakage, and often involves hand-finishing steps such as etching or hand-painting. Buyers who need the shortest possible lead time should prioritize plastic or aluminum drinkware; buyers who prioritize premium quality should expect stainless steel or glass to add a week or more to the timeline.

Customization Method: Laser engraving adds zero additional days to the baseline production timeline because it is fast, requires no drying or curing, and can be performed immediately after the drinkware is manufactured. UV printing adds 2 to 3 days because the printed surface must cure under UV light for 12 to 24 hours to ensure adhesion and durability. Screen printing adds 3 to 5 days for multi-color designs because each color requires a separate pass, and each pass must dry before the next color is applied. Pad printing, commonly used for small logos on curved surfaces, adds 2 to 4 days. Full-color wraparound printing, which involves printing a design that covers the entire surface of the drinkware, adds 5 to 7 days because it requires precise alignment, multiple passes, and extended curing time. Buyers who prioritize speed should choose laser engraving; buyers who require full-color designs should plan for an additional week.

Custom Color Matching: Standard powder coating colors (black, white, navy, red) are typically in stock and add no additional time to production. Custom Pantone color matching requires the supplier to order a custom batch of powder coating from their upstream vendor, which adds 5 to 7 business days to the timeline. The supplier must also perform test coatings to ensure the color matches the Pantone specification, which adds another 1 to 2 days. For orders requiring multiple custom colors—such as a drinkware line with different colors for different product SKUs—each additional color adds 3 to 5 days to the timeline. Buyers who can accept standard colors will save a week; buyers who require exact Pantone matching should add 7 to 10 days to the baseline timeline.

Component Customization: Standard lids, straws, and handles are typically in stock and add no additional time. Custom components—such as bamboo lids, copper-plated handles, or silicone sleeves with embossed logos—must be ordered from specialty suppliers, which adds 10 to 14 days to the timeline. Custom molds for unique lid shapes or handle designs can add 30 to 60 days if the mold does not already exist. Buyers who want to minimize lead time should accept standard components; buyers who require custom components should plan for an additional two weeks or more, and should consider whether the customization is worth the delay.

Compliance Testing and Regulatory Requirements: The Hidden Lead Time Killer

One of the most frequently overlooked factors in custom drinkware lead time is compliance testing. In the United States, drinkware that comes into contact with food or beverages must comply with FDA regulations for food-contact materials, California Proposition 65 requirements for heavy metal content, and CPSIA standards for lead content if the drinkware is marketed to children. For first-time orders from a new supplier or for new product designs, these compliance tests must be performed before the drinkware can be legally sold in the US market. The testing process is not instantaneous, and it is not optional. Buyers who fail to account for compliance testing time are at risk of receiving a shipment that cannot be distributed until the tests are complete, which effectively extends the lead time by two to three weeks after the drinkware has already arrived.

FDA Food-Contact Material Testing: The FDA requires that materials used in drinkware do not leach harmful substances into food or beverages. Testing involves exposing the drinkware to food simulants (such as acetic acid or ethanol) under elevated temperatures and measuring the migration of substances from the material into the simulant. The testing process takes 10 to 14 business days from the time the sample is submitted to the lab, and it costs approximately $500 to $800 per material type. For drinkware with multiple components—such as a stainless steel body, a plastic lid, and a silicone gasket—each component must be tested separately, which multiplies both the cost and the time. Buyers who are ordering from a supplier for the first time should request existing FDA test reports; if the supplier cannot provide them, the buyer should add two to three weeks to the lead time for testing.

California Proposition 65 Heavy Metal Testing: Proposition 65 requires that products sold in California carry a warning label if they contain certain heavy metals (such as lead, cadmium, or mercury) above specified thresholds. Testing involves chemical analysis of the drinkware materials to measure heavy metal content, and it takes 7 to 10 business days at a cost of approximately $300 to $500 per sample. Even if the drinkware is not sold in California, many national retailers and corporate buyers require Prop 65 compliance as a standard procurement requirement, because they do not want to manage separate inventory for California versus other states. Buyers should request Prop 65 test reports from the supplier before placing the order; if the supplier cannot provide them, the buyer should add one to two weeks to the lead time.

CPSIA Lead Content Testing: The Consumer Product Safety Improvement Act (CPSIA) limits lead content in products intended for children under 12 years old. If the drinkware is marketed as a kids' product—such as a sippy cup, a children's water bottle, or a school lunch thermos—it must be tested for lead content, which takes 7 to 10 business days at a cost of approximately $200 to $400 per sample. Even if the drinkware is not explicitly marketed to children, buyers should consider whether the product could reasonably be used by children, because the CPSIA applies based on intended use, not just marketing claims. Buyers who are ordering children's drinkware should add one to two weeks to the lead time for CPSIA testing.

The cumulative impact of compliance testing can extend total lead time by three to four weeks for first-time orders. However, once the testing is complete and the supplier has the test reports on file, repeat orders of the same product do not require additional testing, which means the compliance testing time is a one-time cost. Buyers who plan to place multiple orders over time should prioritize suppliers who already have FDA, Prop 65, and CPSIA test reports for their products, because this eliminates the testing delay for the first order. Buyers who are working with a new supplier or a new product design should request test reports during the quoting phase, not after the order is placed, because discovering that testing is required after production has started can delay delivery by a month or more.

Seasonal Capacity Constraints and Peak Season Lead Time Extensions

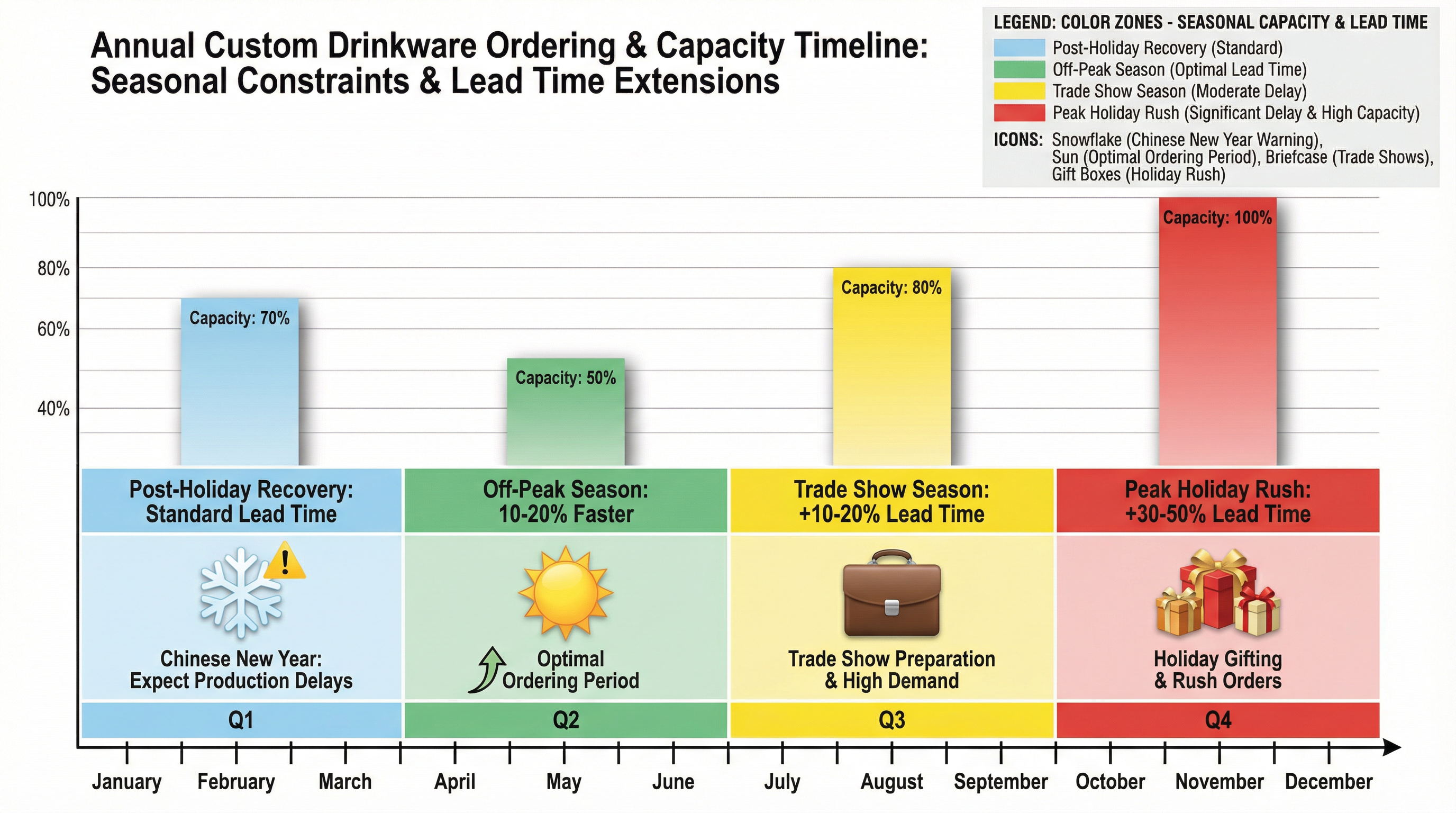

Custom drinkware production is not a constant-capacity industry. Suppliers experience significant seasonal fluctuations in order volume, and these fluctuations directly affect lead time. During peak seasons—primarily Q4 (October through December) for holiday corporate gifting and Q3 (July through September) for back-to-school and fall trade shows—suppliers are operating at or near full capacity, which means new orders must wait for available production slots. During off-peak seasons—primarily Q2 (April through June)—suppliers have excess capacity and can often complete orders faster than the standard tiBuyers who understand these seasonal patterns can time their orders to minimize lead time and avoid the surcharges that suppliers impose during peak periods.

Annual timeline showing how seasonal demand affects custom drinkware production capacity and lead times. Q2 (April-June) offers the fastest lead times, while Q4 (October-December) experiences significant delays due to holiday gifting demand.

Annual timeline showing how seasonal demand affects custom drinkware production capacity and lead times. Q2 (April-June) offers the fastest lead times, while Q4 (October-December) experiences significant delays due to holiday gifting demand.

Q4 Holiday Gifting Rush (October-December): This is the busiest period for custom drinkware suppliers, driven by corporate holiday gifts, year-end employee appreciation programs, and promotional campaigns tied to Black Friday, Cyber Monday, and the winter holiday season. Suppliers receive a disproportionate volume of orders during this period, and production capacity becomes the limiting factor. Lead times that are normally 14 to 18 days can extend to 21 to 28 days or more, because new orders must wait for earlier orders to clear the production queue. Suppliers also impose peak season surcharges of 10% to 20% on orders placed after October 1st, because they know that buyers have limited alternatives and are willing to pay a premium to secure delivery before the holidays. Buyers who need drinkware for December delivery should place orders by mid-September to avoid peak season delays and surcharges. Buyers who wait until October or November will face extended lead times, higher costs, and a higher risk of delivery delays.

Q3 Trade Show and Back-to-School Season (July-September): The fall trade show season and back-to-school promotions create a secondary peak in demand for custom drinkware. Trade shows in industries such as technology, healthcare, and finance are concentrated in September and October, and companies ordering promotional drinkware for these events typically place orders in July and August. Lead times during this period extend by 10% to 20% compared to off-peak periods, and suppliers may require longer advance notice for large orders. Buyers who need drinkware for September trade shows should place orders by early July to ensure delivery before the event. Buyers who wait until August will face tighter timelines and may need to pay rush fees to secure delivery.

Q2 Off-Peak Season (April-June): This is the slowest period for custom drinkware suppliers, and it offers the best opportunity for buyers to negotiate shorter lead times and better pricing. Suppliers have excess production capacity during this period, and they are often willing to expedite orders at no additional cost or to offer discounts to fill their production schedules. Lead times that are normally 14 to 18 days can be compressed to 10 to 14 days during Q2, and suppliers are more flexible about accommodating rush requests or design changes. Buyers who have flexibility in their ordering schedule should prioritize Q2 for placing orders, because they will receive faster delivery, lower pricing, and more responsive customer service.

Chinese New Year and Golden Week (January-February, October): Buyers who source custom drinkware from overseas suppliers must account for Chinese New Year (late January or early February) and Golden Week (October 1-7), during which factories in China close for one to three weeks. Orders placed in December or January will be delayed by Chinese New Year, and orders placed in late September will be delayed by Golden Week. Buyers who need drinkware delivered in February or March should place orders by early December to ensure production is complete before Chinese New Year. Buyers who need drinkware delivered in November should place orders by early September to avoid Golden Week delays. Failing to account for these holidays can add three to four weeks to the lead time, because production stops entirely during these periods.

Domestic vs Overseas Sourcing: The Lead Time Trade-Off

One of the most consequential decisions in custom drinkware procurement is whether to source domestically or overseas. Domestic suppliers in the USA offer significantly shorter lead times—typically two to three weeks for production plus three to seven days for shipping—but they charge higher per-unit prices, typically 15% to 30% more than overseas suppliers. Overseas suppliers, primarily located in China, Taiwan, and Vietnam, offer lower per-unit prices but require six to eight weeks for ocean freight shipping or four to five weeks for air freight, plus an additional one to two weeks for customs clearance. The choice between domestic and overseas sourcing is not just a cost decision; it is a lead time decision, and buyers must weigh the time savings of domestic sourcing against the cost savings of overseas sourcing.

Domestic Sourcing (USA): Domestic suppliers offer the shortest total lead time, typically three to four weeks from order placement to delivery. This includes 5 to 7 days for design finalization, 14 to 18 days for production, and 3 to 7 days for ground shipping. Domestic suppliers also offer more flexibility for rush orders, because they can expedite production without the constraints of international shipping schedules. A domestic supplier might be able to complete a rush order in 10 to 14 days with a 20% to 30% surcharge, which is still faster than the standard timeline for overseas sourcing. Domestic suppliers are also easier to communicate with, because they operate in the same time zone and speak the same language, which reduces the risk of miscommunication and design errors. The primary disadvantage of domestic sourcing is cost: per-unit prices are typically $1.50 to $3.00 higher than overseas suppliers for comparable products, which can add $1,500 to $3,000 to the total cost of a 1,000-unit order.

Overseas Sourcing (China, Taiwan, Vietnam): Overseas suppliers offer the lowest per-unit prices, typically 15% to 30% lower than domestic suppliers, but they require significantly longer lead times. Ocean freight shipping takes 30 to 45 days from the port of origin to the destination port, plus an additional 3 to 7 days for customs clearance and inland transportation. Total lead time from order placement to delivery is typically six to eight weeks, which includes 5 to 7 days for design finalization, 30 to 45 days for production and shipping, and 3 to 7 days for customs clearance. Air freight reduces shipping time to 7 to 10 days, but it increases shipping costs by 300% to 500%, which can eliminate the cost advantage of overseas sourcing. Overseas suppliers are also more difficult to communicate with due to time zone differences and language barriers, which increases the risk of design errors and delays. Buyers who choose overseas sourcing must plan orders eight to ten weeks in advance to ensure delivery by the target date, and they should add a 20% buffer to account for potential delays in customs clearance or shipping.

The decision between domestic and overseas sourcing depends on the buyer's priorities. Buyers who prioritize speed, flexibility, and ease of communication should choose domestic suppliers, even if it means paying a higher per-unit price. Buyers who prioritize cost savings and are willing to plan orders well in advance should choose overseas suppliers, but they must account for the longer lead time and the higher risk of delays. For orders with tight deadlines—such as trade show giveaways or product launch events—domestic sourcing is almost always the better choice, because the cost of a late delivery far exceeds the cost savings of overseas sourcing.

Enterprise Scale Recommendations: Tailoring Lead Time Strategies to Company Size

The optimal lead time strategy for custom drinkware procurement varies significantly based on company size, order volume, and organizational complexity. Startups and small businesses typically place smaller orders (200 to 500 units) and need faster turnaround times to respond to market opportunities. Mid-size companies (500 to 2,000 units) balance cost and speed, and they often have more predictable ordering schedules. Large enterprises (2,000+ units) prioritize cost efficiency and supply chain reliability, and they are willing to plan orders months in advance to secure the best pricing. Each segment requires a different approach to managing lead time, and buyers who apply a one-size-fits-all strategy are either overpaying for speed they do not need or underestimating the time required to deliver large, complex orders.

Startups and Small Businesses (200-500 Units): For small orders, the priority is speed and flexibility. Startups often need custom drinkware for last-minute events, investor meetings, or product launches, and they cannot afford to wait two months for delivery. The best strategy for this segment is to prioritize domestic suppliers, accept standard materials and colors, and choose laser engraving over UV or screen printing. Domestic suppliers can typically deliver 200 to 500 units in three to four weeks, and they are more willing to accommodate rush requests for small orders because the orders can fit into production gaps. Small businesses should also avoid custom packaging and specialty components, because these add time and cost without delivering proportional value for small order volumes. The per-unit price will be higher than overseas sourcing—typically $10 to $15 per unit for stainless steel tumblers versus $7 to $10 per unit from overseas suppliers—but the time savings and reduced risk of delays justify the premium.

Mid-Size Companies (500-2,000 Units): For mid-size orders, the priority is balancing cost and speed. Companies in this segment have more predictable ordering schedules and can plan orders six to eight weeks in advance, which opens the option of overseas sourcing with air freight. Air freight from overseas suppliers reduces shipping time to 7 to 10 days, which brings total lead time to four to five weeks—only slightly longer than domestic sourcing but at a 15% to 20% cost savings. Mid-size companies should request quotes from both domestic and overseas suppliers and compare total cost of ownership, including shipping, customs duties, and rush fees. For orders with flexible deadlines, overseas sourcing with ocean freight offers the best cost savings. For orders with tight deadlines, domestic sourcing offers the best reliability. Mid-size companies should also consider establishing relationships with multiple suppliers—one domestic and one overseas—so they have options depending on the urgency of each order.

Large Enterprises (2,000+ Units): For large orders, the priority is cost efficiency and supply chain reliability. Enterprises in this segment typically place orders 10 to 12 weeks in advance, which allows them to use ocean freight from overseas suppliers and secure the lowest per-unit pricing. Large orders also benefit from negotiating dedicated production slots with suppliers, which guarantees that the order will be completed on schedule without competing for capacity with other orders. Enterprises should work with suppliers to establish annual contracts or volume commitments, which provide predictable pricing and priority access to production capacity during peak seasons. Large enterprises should also invest in compliance testing upfront—requesting FDA, Prop 65, and CPSIA test reports for all products they plan to order—so that repeat orders do not require additional testing time. The per-unit cost savings from overseas sourcing can be substantial for large orders: a 10,000-unit order might cost $70,000 from an overseas supplier versus $90,000 from a domestic supplier, a savings of $20,000 that justifies the longer lead time.

Risk Mitigation Strategies: How to Avoid Lead Time Disasters

Even with careful planning, lead time delays can occur due to unforeseen circumstances: a supplier's production line breaks down, a shipment is delayed at customs, a design error is discovered after production has started, or a key component is out of stock. Buyers who do not have contingency plans for these scenarios are at risk of missing critical deadlines, and they often end up paying exorbitant rush fees or accepting substandard products to meet their delivery dates. The most effective risk mitigation strategy is to build buffer time into the lead time calculation, but there are also specific tactics that reduce the likelihood of delays and provide fallback options when delays do occur.

Always Add a 20% Buffer to the Supplier's Quoted Lead Time: Suppliers quote lead times based on ideal conditions: no design revisions, no material shortages, no production line breakdowns, and no shipping delays. In reality, at least one of these factors will affect most orders, and the cumulative impact can add one to two weeks to the delivery date. Buyers should calculate lead time as 120% of the supplier's quoted timeline. If the supplier quotes four weeks, the buyer should plan for five weeks. This buffer accounts for the unexpected delays that occur in nearly every order, and it ensures that even if something goes wrong, the drinkware will still arrive before the deadline. Buyers who do not build in buffer time are gambling that everything will go perfectly, and that gamble rarely pays off.

Request Sample Approval Before Full Production: For first-time orders or orders with complex customization, buyers should request a physical sample before the supplier begins full production. The sample allows the buyer to verify that the logo placement is correct, the colors match the brand guidelines, and the product quality meets expectations. Sample production adds one to two weeks to the lead time, but it prevents costly mistakes that can delay the entire order. If the sample reveals an error—such as a logo that is too small, a color that does not match, or a material that feels cheap—the buyer can request corrections before the supplier produces thousands of units. Correcting an error after full production has started can add two to three weeks to the lead time and may require scrapping the entire batch, which is far more expensive than the cost of a sample.

Avoid Ordering During Chinese New Year or Golden Week: Buyers who source from overseas suppliers should avoid placing orders in December (which will be delayed by Chinese New Year in January or February) or late September (which will be delayed by Golden Week in early October). If the order must be placed during these periods, the buyer should confirm with the supplier that production will be completed before the holiday shutdown, or plan for an additional three to four weeks of delay. Suppliers are often reluctant to disclose holiday closures until the buyer asks directly, so buyers should proactively inquire about holiday schedules during the quoting phase.

Establish Backup Supplier Relationships: Buyers who rely on a single supplier are vulnerable to capacity constraints, production delays, or quality issues that can derail an entire order. Establishing relationships with multiple suppliers—ideally one domestic and one overseas—provides fallback options when the primary supplier cannot meet the deadline. If the primary supplier quotes a six-week lead time and the buyer needs delivery in four weeks, the buyer can request a quote from the backup supplier, who may have available capacity and can deliver faster. Maintaining backup supplier relationships requires placing occasional orders with the backup supplier to keep the relationship active, but the cost of these occasional orders is far less than the cost of a missed deadline when the primary supplier cannot deliver.

Calculating Your Custom Drinkware Lead Time: A Practical Framework

The most reliable way to estimate lead time for a custom drinkware order is to break the process into discrete phases and calculate the duration of each phase based on the specific characteristics of the order. This framework provides a structured approach to lead time calculation and ensures that buyers account for all the variables that affect delivery dates.

Step 1: Design Finalization (5-10 Business Days): Add 5 days if the buyer has vector artwork ready and internal approvals are consolidated. Add 10 days if the buyer needs design assistance, multiple revision rounds, or complex internal approval processes.

Step 2: Material Procurement (3-7 Business Days): Add 3 days for standard materials and colors. Add 7 days for custom Pantone colors or specialty components.

Step 3: Production (10-21 Business Days): Add 10 days for plastic bottles with laser engraving. Add 14 days for stainless steel tumblers with laser engraving. Add 18 days for stainless steel tumblers with UV printing or screen printing. Add 21 days for ceramic mugs or glass drinkware with full-color printing.

Step 4: Compliance Testing (0-21 Business Days): Add 0 days if the supplier has existing FDA, Prop 65, and CPSIA test reports. Add 14 days for FDA and Prop 65 testing if reports are not available. Add 21 days if CPSIA testing is also required.

Step 5: Quality Control and Packaging (3-7 Business Days): Add 3 days for standard packaging. Add 7 days for custom packaging or retail-ready displays.

Step 6: Shipping (3-45 Business Days): Add 3-7 days for domestic ground shipping. Add 1-3 days for domestic air shipping. Add 30-45 days for overseas ocean freight. Add 7-10 days for overseas air freight.

Step 7: Buffer (20% of Total): Multiply the total of Steps 1-6 by 1.2 to add a 20% buffer for unexpected delays.

Example Calculation (Domestic Supplier, Standard Order):

- Design Finalization: 5 days

- Material Procurement: 3 days

- Production (stainless steel, laser engraving): 14 days

- Compliance Testing (existing reports): 0 days

- Quality Control and Packaging: 3 days

- Shipping (domestic ground): 5 days

- Subtotal: 30 days

- Buffer (20%): 6 days

- Total Lead Time: 36 days (approximately 7 weeks)

Example Calculation (Overseas Supplier, Custom Order):

- Design Finalization: 10 days

- Material Procurement (custom Pantone color): 7 days

- Production (stainless steel, UV printing): 18 days

- Compliance Testing (FDA + Prop 65): 14 days

- Quality Control and Packaging (custom packaging): 7 days

- Shipping (ocean freight): 40 days

- Subtotal: 96 days

- Buffer (20%): 19 days

- Total Lead Time: 115 days (approximately 23 weeks)

This framework demonstrates why lead time varies so dramatically based on the specific characteristics of the order. A simple domestic order with standard materials and laser engraving can be completed in seven weeks, while a complex overseas order with custom colors, UV printing, compliance testing, and custom packaging requires 23 weeks. Buyers who do not account for these variables are systematically underestimating lead time and setting themselves up for delivery delays.

Frequently Asked Questions About Custom Drinkware Lead Time

Q: Can I get custom drinkware delivered in two weeks? A: Two-week delivery is possible only for small orders (200-500 units) from domestic suppliers using standard materials, standard colors, and laser engraving. The buyer must have vector artwork ready, approve the proof within 24 hours, and pay for expedited shipping. A 20% to 30% rush fee will typically apply. Overseas suppliers cannot deliver in two weeks under any circumstances due to shipping time.

Q: Why does custom Pantone color matching add so much time to the lead time? A: Custom Pantone colors require the supplier to order a custom batch of powder coating from their upstream vendor, which takes 5 to 7 business days. The supplier must also perform test coatings to ensure the color matches the Pantone specification, which adds another 1 to 2 days. Standard colors are kept in stock, so they add no additional time.

Q: Do I need FDA testing for every order, or just the first order? A: FDA testing is required only once per product design and material combination. If you order the same product from the same supplier using the same materials, the existing test reports remain valid for repeat orders. However, if you change the material, the supplier, or the product design, new testing is required.

Q: How much does rush production cost, and how much time does it save? A: Rush production typically carries a 20% to 40% surcharge on the base product price and can reduce lead time by 30% to 40%. For example, a standard four-week lead time might be compressed to 2.5 to 3 weeks with rush production. However, rush production is not available for all products, and it typically requires accepting standard materials, colors, and customization methods.

Q: What is the best time of year to order custom drinkware to minimize lead time? A: Q2 (April through June) is the best time to order, because suppliers have excess capacity and can often complete orders 10% to 20% faster than the standard timeline. Q4 (October through December) is the worst time to order, because suppliers are at full capacity and lead times extend by 30% to 50%.

Q: Should I choose domestic or overseas sourcing if I need the shortest possible lead time? A: Domestic sourcing offers the shortest lead time, typically three to four weeks from order placement to delivery. Overseas sourcing requires six to eight weeks for ocean freight or four to five weeks for air freight. If lead time is the primary concern, domestic sourcing is almost always the better choice, even if it costs 15% to 30% more per unit.

Next Steps: How to Secure Reliable Custom Drinkware Delivery

Understanding lead time is only the first step. The next step is finding a supplier who can deliver on their quoted timeline, communicate proactively about potential delays, and provide the quality and customization options your brand requires. At DrinkwareWorks USA, we specialize in helping US businesses navigate the complexities of custom drinkware procurement. Our domestic production facilities offer three to four week lead times for standard orders, and we maintain transparent communication throughout the entire process—from design finalization to delivery. We provide upfront FDA, Prop 65, and CPSIA test reports for all our products, so you never have to worry about compliance delays. And we offer flexible rush production options for urgent orders, with clear pricing and realistic timelines.

If you are planning a custom drinkware order and need reliable delivery by a specific date, we invite you to explore our custom drinkware solutions and request a quote. Our team will work with you to calculate an accurate lead time based on your specific requirements, identify potential risks, and recommend the best materials and customization methods to meet your deadline without compromising quality. Whether you need 200 units for a product launch or 10,000 units for a national corporate gifting program, we have the capacity, the expertise, and the commitment to deliver on time, every time.