When a supplier quotes "eight weeks," most buyers mark their calendar for delivery eight weeks from order placement. The assumption feels reasonable—lead time should mean the time between initiating an order and receiving the goods. Yet this seemingly straightforward interpretation is where a significant portion of delivery miscalculations originate. The term "lead time" carries no universal definition across the custom drinkware supply chain, and the gap between what buyers assume and what suppliers communicate routinely creates three- to five-week delivery shortfalls that disrupt event timelines and inventory planning.

The core issue is not that suppliers intentionally mislead buyers. Rather, different suppliers measure lead time from different starting points and to different endpoints, depending on their operational structure, geographic location, and internal workflow conventions. A factory in Guangdong might quote lead time as "production completion to FOB Shenzhen port." A U.S.-based importer-distributor might quote lead time as "order confirmation to arrival at their California warehouse, excluding final mile delivery to the buyer's facility." A domestic contract manufacturer might quote lead time as "design approval to production completion, excluding powder coating cure time and shipping." Each interpretation is internally consistent within that supplier's operations, but when buyers compare quotes without clarifying these definitions, they are effectively comparing incompatible metrics.

In practice, this is often where lead time decisions start to be misjudged. A procurement manager receives three quotes: Supplier A quotes six weeks, Supplier B quotes eight weeks, Supplier C quotes ten weeks. The natural instinct is to select Supplier A for the shortest timeline. However, if Supplier A's six weeks excludes ocean freight, customs clearance, and inland transport (adding four weeks), while Supplier B's eight weeks includes everything through delivery to the buyer's dock, then Supplier A's actual delivery timeline is ten weeks—longer than Supplier B. The buyer who selected based on the quoted number now faces a two-week delay they did not anticipate, and by the time this becomes apparent, it is often too late to switch suppliers or adjust event schedules.

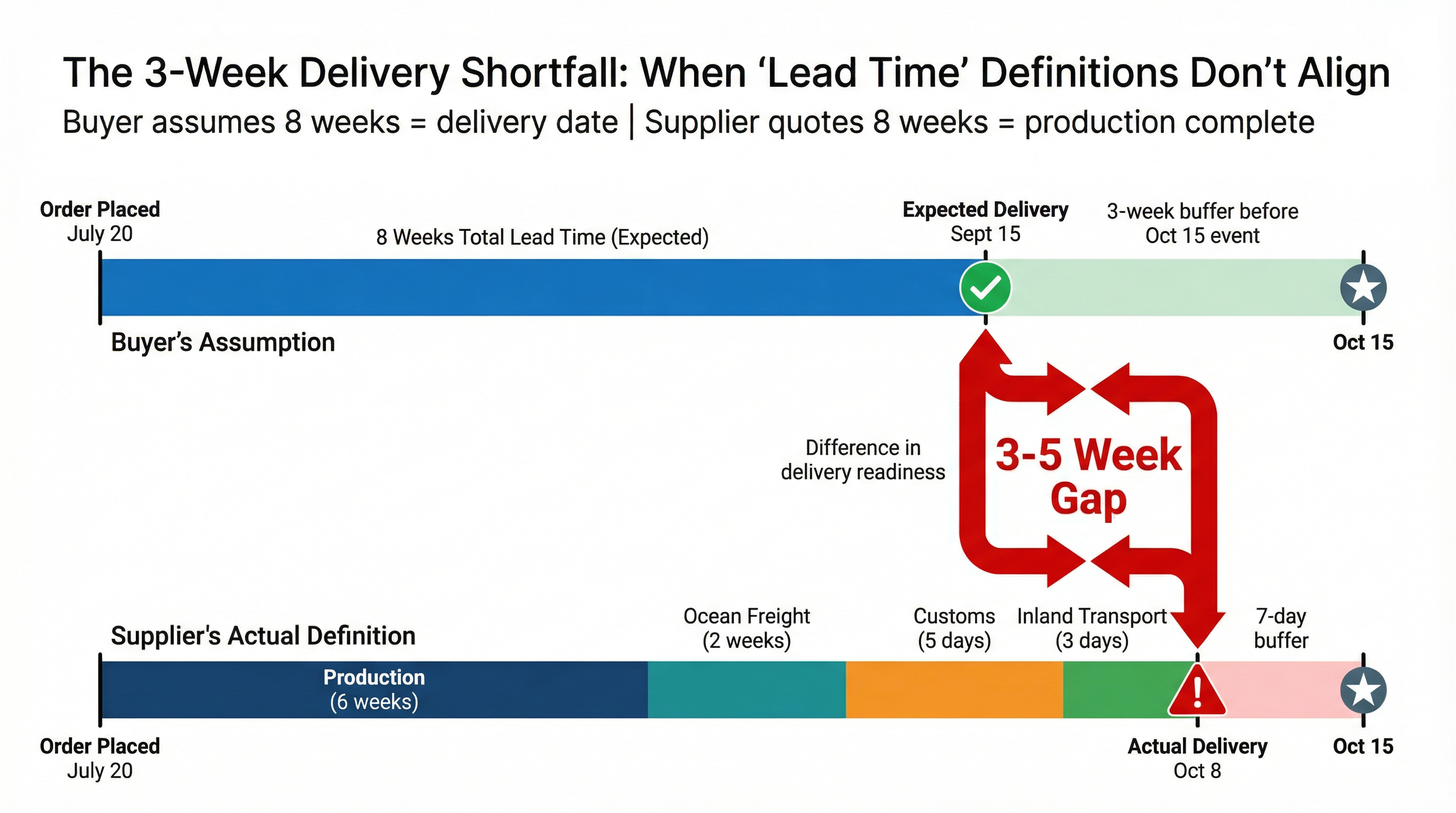

The ambiguity compounds when buyers attempt to calculate backward from a fixed deadline. Consider a corporate event scheduled for October 15, requiring 1,000 custom stainless steel tumblers. The buyer solicits quotes in July and receives an "eight-week lead time" from a preferred supplier. Assuming eight weeks means delivery by mid-September, the buyer places the order on July 20, expecting a comfortable three-week buffer before the event. The supplier, however, interprets "eight-week lead time" as production completion—the point at which finished goods are ready to ship from their facility. Ocean freight from Shanghai to Los Angeles adds two weeks. Customs clearance adds another five to seven days. Inland trucking from the port to the buyer's distribution center adds three days. The actual delivery date becomes October 8, leaving the buyer with seven days instead of the anticipated 25 days to distribute tumblers to multiple event locations. What appeared to be prudent advance planning becomes a logistical scramble because the buyer and supplier were operating under different definitions of the same term.

This communication breakdown is not limited to overseas sourcing. Domestic suppliers also vary in how they define lead time, particularly when their supply chains include imported components. A U.S.-based drinkware supplier might quote a four-week lead time, and buyers reasonably assume this represents a significant advantage over the twelve-week timelines associated with direct imports from Asia. However, if that domestic supplier sources stainless steel blanks, silicone gaskets, and powder coating materials from overseas, their four-week quote may only cover the domestic assembly and customization phase. The actual timeline includes six weeks for component import, plus the four-week domestic lead time, totaling ten weeks—only marginally faster than direct import, and significantly longer than the buyer anticipated when selecting a domestic supplier specifically to shorten lead time.

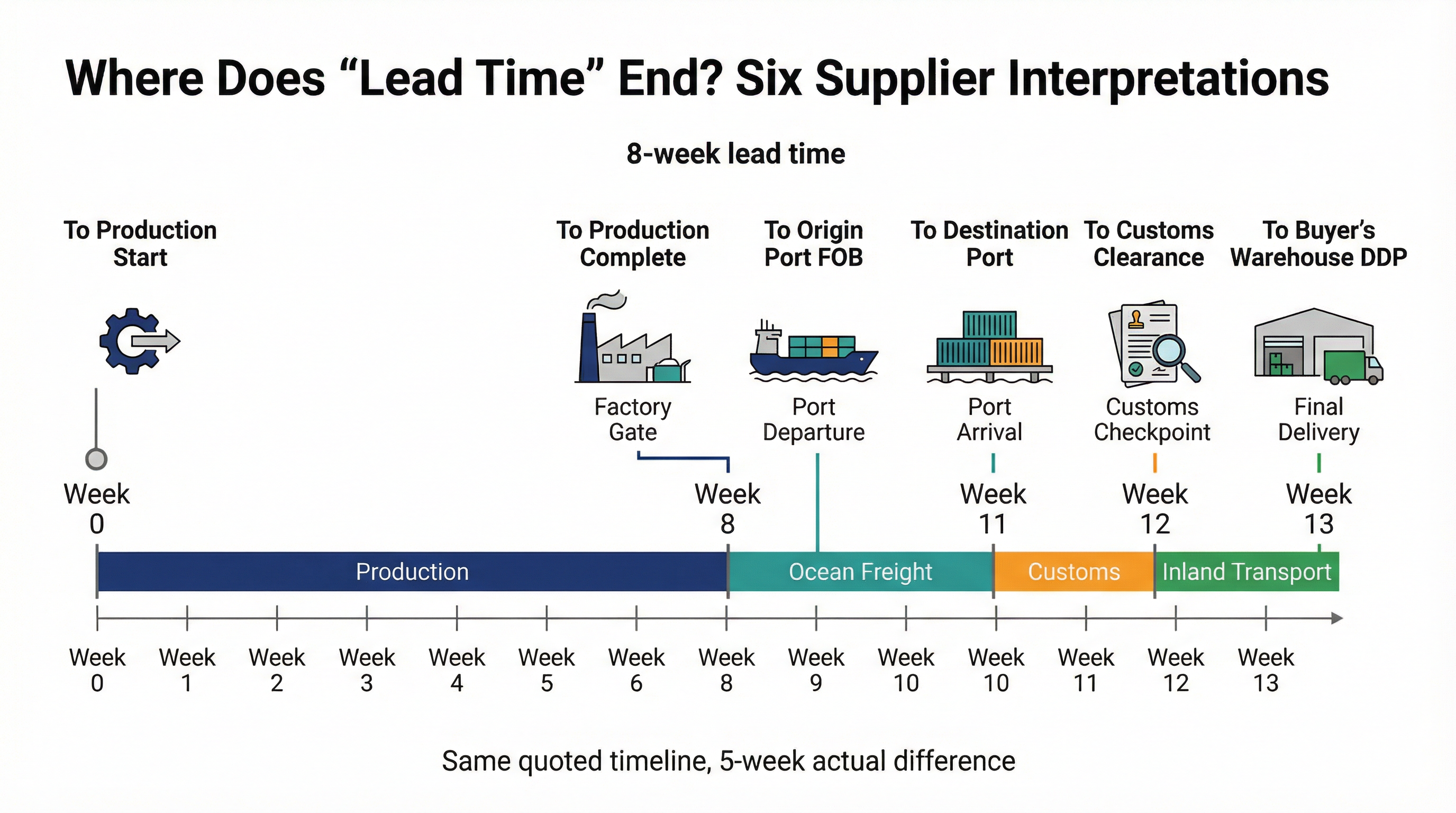

Where does "lead time" end? Six common supplier interpretations of the same quoted timeline

Where does "lead time" end? Six common supplier interpretations of the same quoted timeline

The variability in lead time definitions stems from legitimate differences in how suppliers structure their operations and where they hand off responsibility to the buyer. Factories that operate on an FOB (Free On Board) basis consider their obligation complete once goods are loaded onto a vessel at the origin port. Their lead time quote reflects production and domestic logistics within the manufacturing country, but excludes international shipping, customs clearance, and destination-country transport. Suppliers operating on a DDP (Delivered Duty Paid) basis, by contrast, retain responsibility through final delivery to the buyer's specified location, and their lead time quote reflects the entire end-to-end timeline. A buyer comparing an FOB quote of six weeks with a DDP quote of nine weeks might perceive a three-week difference, when in reality the FOB option requires the buyer to arrange and account for an additional four weeks of logistics, making the true timelines six weeks versus nine weeks—a much smaller gap than the quoted figures suggest.

The problem intensifies when buyers work with multiple suppliers across different sourcing models. A buyer managing a product line that includes ceramic mugs from a domestic supplier, stainless steel tumblers from an overseas factory, and glass water bottles from a third-party importer must navigate three different lead time definitions simultaneously. The domestic supplier quotes lead time to their warehouse, the overseas factory quotes lead time to FOB origin port, and the importer quotes lead time to the buyer's receiving dock. Without explicit clarification, the buyer's internal planning spreadsheet treats all three timelines as equivalent, leading to staggered deliveries that disrupt inventory availability and create fulfillment bottlenecks.

Another dimension of the ambiguity involves whether lead time includes or excludes pre-production activities. Some suppliers quote lead time starting from order confirmation, while others quote lead time starting from design approval or sample approval. For custom drinkware orders requiring logo artwork, the gap between these two starting points can be one to two weeks. A buyer who submits an order on August 1 and receives an "eight-week lead time" quote might expect delivery by September 26. If the supplier's eight-week clock does not start until artwork is approved—and the approval process takes ten days due to internal stakeholder review—the actual delivery date shifts to October 6, creating a ten-day shortfall. The buyer assumed the lead time clock started when the purchase order was issued, but the supplier's internal workflow treats artwork approval as the trigger point for production scheduling.

The 3-week delivery shortfall: when buyer and supplier define "lead time" differently, the result is missed deadlines and compressed distribution windows

The 3-week delivery shortfall: when buyer and supplier define "lead time" differently, the result is missed deadlines and compressed distribution windows

The consequences of these misalignments extend beyond individual orders. When buyers consistently experience delivery dates that lag quoted lead times by three to five weeks, they begin to build informal buffers into their planning—ordering earlier than necessary, inflating safety stock, or avoiding certain suppliers altogether. These adaptive behaviors create inefficiencies across the supply chain. Buyers who order four weeks earlier than needed tie up working capital in inventory that sits idle. Suppliers who lose business due to perceived unreliability may actually have been offering competitive timelines, but their lead time definition did not align with buyer expectations. The lack of standardized terminology imposes a coordination cost on the entire industry, as each buyer-supplier relationship must independently negotiate and clarify definitions that could otherwise be assumed.

The challenge for buyers is that lead time definitions are rarely stated explicitly in RFQ responses or quotations. Suppliers assume their definition is self-evident or standard within their segment of the industry, and buyers assume suppliers are quoting end-to-end timelines because that is what the buyer needs to plan around. Neither party recognizes the misalignment until a delivery date approaches and the buyer inquires about shipment tracking, only to discover that the goods have not yet left the factory because the supplier's quoted lead time referred to production completion, not delivery.

Addressing this issue requires buyers to adopt a more granular approach to lead time inquiry during the RFQ phase. Rather than asking "What is your lead time?" and accepting a single number, buyers should ask a series of clarifying questions: Does your lead time include design approval time, or does the clock start after artwork is finalized? Does your lead time end at production completion, at shipment from your facility, at arrival at the destination port, after customs clearance, or at delivery to our specified address? If your lead time is quoted FOB, what is the typical duration for ocean freight, customs clearance, and inland transport to our region? These questions force both parties to align on a shared understanding of the timeline before commitments are made.

For buyers managing multiple suppliers, creating a standardized lead time framework can reduce confusion. One approach is to request that all suppliers provide lead time broken into stages: pre-production (design approval, sample approval), production (manufacturing, quality control, packaging), and logistics (domestic transport to port, ocean freight, customs clearance, inland delivery). This stage-based breakdown allows buyers to compare suppliers on an apples-to-apples basis, even when their operational models differ. A supplier quoting six weeks for production plus four weeks for logistics is directly comparable to a supplier quoting ten weeks end-to-end, and the buyer can make an informed decision based on which stages they are willing to manage internally versus outsource to the supplier.

Another strategy involves specifying the desired lead time definition in the RFQ itself. A buyer might state: "Please provide lead time from purchase order issuance to delivery at our warehouse in Chicago, including all production, shipping, customs clearance, and inland transport." This approach eliminates ambiguity by defining the start and end points upfront, ensuring that all supplier responses are measured against the same standard. Suppliers who cannot meet that definition—perhaps because they only operate FOB and do not arrange destination-country logistics—will either decline to quote or provide a partial timeline with a note that additional logistics must be arranged by the buyer. Either outcome is preferable to receiving a six-week quote that later proves to exclude four weeks of necessary logistics.

The lead time definition ambiguity also affects how buyers evaluate supplier performance over time. A buyer who tracks on-time delivery rates might penalize a supplier for "late" deliveries when, in fact, the supplier met their internally defined lead time, and the delay occurred in logistics stages the supplier never claimed to control. Conversely, a buyer might continue working with a supplier who consistently delivers two weeks later than expected, attributing the delays to "normal variability" rather than recognizing that the supplier's lead time definition excludes critical stages. Accurate performance evaluation requires that both parties agree on what constitutes the delivery commitment, and that agreement must be documented and referenced when assessing outcomes.

For suppliers, the incentive to clarify lead time definitions is not always obvious. A supplier quoting a shorter lead time—even if that lead time excludes logistics—may win more bids in the short term, as buyers gravitate toward the lowest number. However, this approach creates dissatisfaction when actual delivery dates lag expectations, leading to strained relationships, negative reviews, and lost repeat business. Suppliers who proactively clarify their lead time definitions, even if it results in a longer quoted timeline, build trust and reduce the likelihood of disputes. A supplier who states "Our eight-week lead time covers production to FOB Shenzhen; ocean freight to Los Angeles typically adds two weeks, and we can arrange that for you or you can use your own freight forwarder" provides the buyer with the information needed to plan accurately, even if the total timeline is ten weeks rather than eight.

The structural solution to lead time definition ambiguity would be industry-wide adoption of standardized terminology, similar to Incoterms for shipping responsibilities. If the custom drinkware industry agreed on terms such as "Lead Time to Production Complete," "Lead Time to Origin Port," "Lead Time to Destination Port," and "Lead Time to Buyer's Dock," buyers and suppliers could communicate more precisely without lengthy clarifications. However, absent such standardization, the responsibility falls on individual buyers to ask the right questions and on suppliers to provide transparent, stage-based timelines.

In the context of understanding how production timelines are structured, recognizing that lead time is not a monolithic figure but a composite of multiple stages—each of which may or may not be included in a supplier's quote—is essential for accurate planning. Buyers who treat lead time as a single, universally defined metric will continue to encounter delivery shortfalls that disrupt their operations. Those who approach lead time as a negotiated definition, clarified upfront and documented in purchase agreements, will find that their suppliers deliver more consistently to expectations, not because the suppliers have become faster, but because the expectations were aligned with reality from the outset.

The three- to five-week gap between assumed delivery dates and actual delivery dates is not an inevitable feature of custom drinkware procurement. It is a coordination failure rooted in ambiguous terminology, and it can be resolved through more precise communication. The buyer who asks "Does your eight-week lead time include delivery to my warehouse in Denver, or does it end at production completion?" is not being pedantic—they are ensuring that the timeline they are planning around matches the timeline the supplier is committing to. That alignment, more than any optimization of production speed or logistics efficiency, is what determines whether an order arrives when expected or becomes a source of operational disruption.