When a procurement team selects UV printing for their 2,000-unit custom tumbler order because the full-color logo looks stunning on the digital mockup, they are making a design decision. When those same tumblers show visible logo degradation after six months of daily office use—including thrice-weekly dishwasher cycles—they discover they should have been making a durability specification decision. This distinction is where customization process decisions routinely go wrong, and the consequences are both predictable and expensive.

The decoration method selection phase in custom drinkware procurement appears straightforward on the surface. Suppliers present three or four options—laser engraving, UV printing, screen printing, pad printing—with sample images showing how each method renders the buyer's logo. The buyer evaluates visual appeal, compares per-unit costs, and selects the method that delivers the best combination of aesthetics and budget. What this evaluation process systematically omits is the critical question: how will this decoration method perform in the specific use environment where these products will spend their operational life?

In practice, this is often where decoration method decisions start to be misjudged. A UV-printed tumbler destined for a trade show giveaway—where recipients will use it occasionally, hand-wash it gently, and eventually relegate it to a kitchen cabinet—represents a fundamentally different durability requirement than a UV-printed tumbler destined for an employee wellness program, where recipients will use it daily, run it through commercial dishwashers in office kitchens, and expect it to maintain brand presentation for two to three years. The decoration method is identical. The use environment is radically different. The durability outcome will diverge accordingly, and the buyer who failed to specify use environment during the selection phase will bear the consequences.

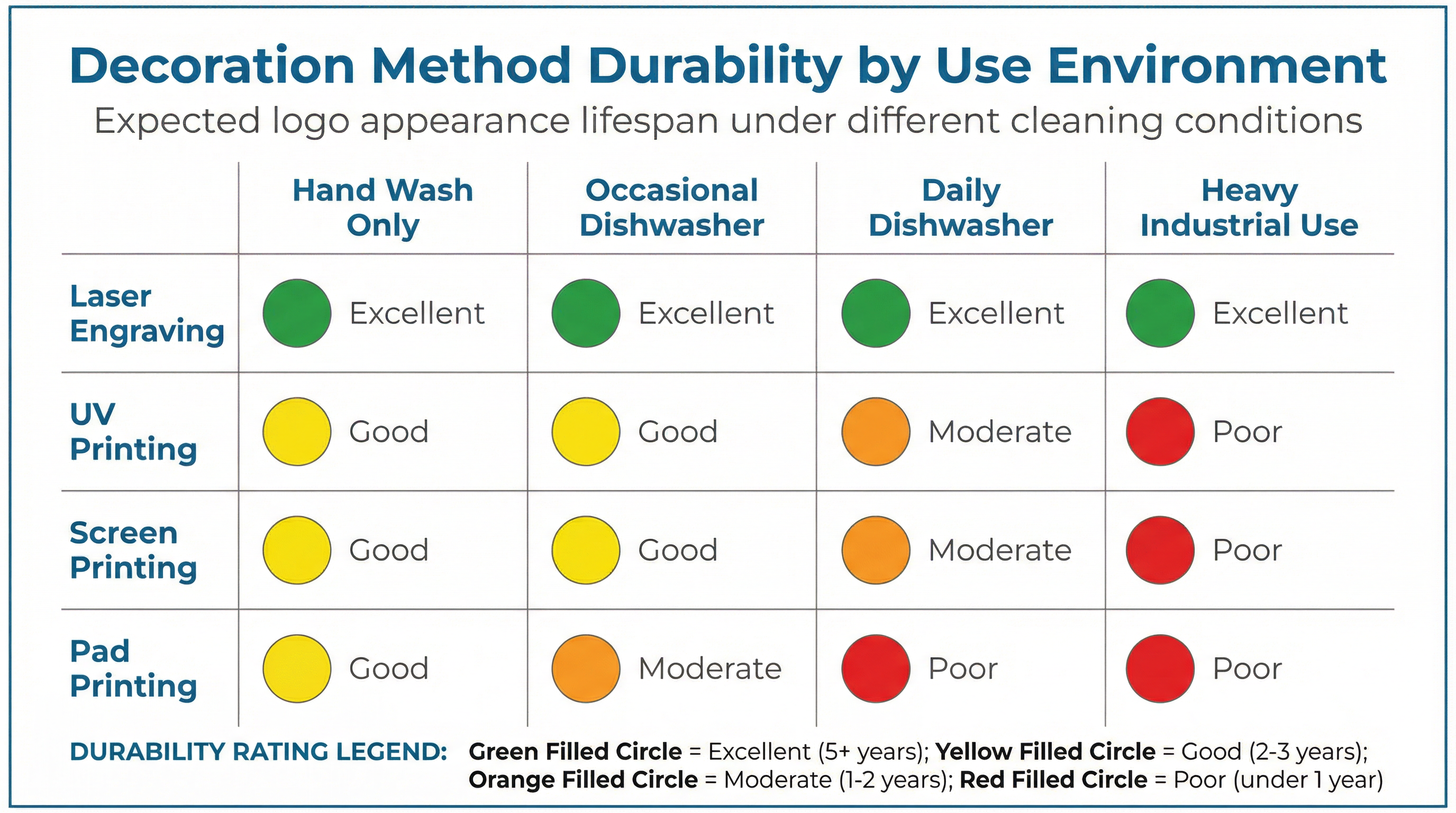

The physics of decoration durability are not mysterious, but they are frequently overlooked in procurement discussions that focus on visual output rather than material science. Laser engraving removes material from the substrate surface—whether powder coating, anodized aluminum, or bare stainless steel—creating a permanent depression that cannot fade, peel, or wash away because there is no applied material to degrade. The logo exists as an absence of surface material, which means it persists for the entire lifespan of the product itself. This permanence comes with trade-offs: laser engraving is monochrome by nature (revealing the underlying metal color), cannot reproduce gradients or photographic images, and creates a subtle rather than vibrant visual impact. For buyers who prioritize longevity over color vibrancy, laser engraving is the appropriate specification. For buyers who prioritize visual impact without understanding the durability implications, laser engraving feels like a compromise they are unwilling to make.

UV printing operates on opposite principles. Special UV-curable inks are applied to the substrate surface and rapidly cured under ultraviolet light, creating a bonded layer that can reproduce full-color images, gradients, metallic effects, and photographic detail. The visual possibilities are substantially broader than laser engraving, which explains why buyers gravitate toward UV printing when evaluating sample images. The durability equation, however, is fundamentally different. UV-printed designs exist as applied material sitting on top of the substrate surface. This applied layer is subject to mechanical abrasion (from handling, bag storage, cup holder friction), chemical exposure (from dishwasher detergents, sanitizing agents, acidic beverages), thermal cycling (from hot beverage contact, dishwasher heat, freezer storage), and UV degradation (from sunlight exposure during outdoor use). Each of these environmental factors progressively degrades the printed layer, with cumulative effects that become visible over time.

The durability gap between laser engraving and UV printing is not a quality control issue—it is a materials physics reality that no amount of supplier quality improvement can eliminate. A UV-printed logo that maintains perfect appearance after 20 dishwasher cycles may show edge lifting after 50 cycles, visible fading after 100 cycles, and significant degradation after 200 cycles. For a tumbler used once weekly and hand-washed, this represents a five-year lifespan with acceptable appearance. For a tumbler used daily and dishwasher-cleaned three times per week, this represents a six-month lifespan before the logo becomes a brand liability rather than a brand asset. The decoration method is identical in both scenarios. The use environment determines the durability outcome.

Screen printing occupies a middle position in the durability spectrum, with characteristics that buyers often misunderstand. Traditional screen printing applies ink through a mesh stencil, creating a thicker ink deposit than UV printing but still an applied layer subject to environmental degradation. Screen-printed logos on ceramic mugs—where the ink is fired at high temperature and becomes part of the glaze—demonstrate excellent durability. Screen-printed logos on stainless steel tumblers—where the ink sits on top of powder coating without high-temperature fusion—demonstrate durability comparable to UV printing, with similar vulnerability to dishwasher cycles and mechanical abrasion. The substrate matters as much as the printing method, and buyers who assume "screen printing" delivers consistent durability across all products are making specification errors based on incomplete information.

The use environment specification gap manifests in procurement workflows that treat decoration method selection as a design decision rather than a durability specification. When buyers submit RFQs that specify "full-color UV printing" without specifying "must maintain brand-acceptable appearance after 300 dishwasher cycles," they are defining visual requirements while leaving durability requirements undefined. Suppliers respond to the specifications they receive. If the specification says "UV printing," the supplier provides UV printing—and the supplier has fulfilled their contractual obligation regardless of whether the logo fades after six months of heavy use. The buyer who expected two-year durability but specified only visual output has created the conditions for their own disappointment.

This specification gap is particularly acute for corporate gifting programs where the intended use environment varies across recipient populations. A 2,000-unit tumbler order distributed to employees across 15 regional offices will encounter radically different use environments depending on recipient behavior. Some recipients will hand-wash carefully and use the tumbler occasionally. Others will run it through industrial dishwashers daily and subject it to years of heavy use. The buyer who selects decoration method based on the gentle-use scenario will receive complaints from the heavy-use population. The buyer who selects decoration method based on the heavy-use scenario may pay a premium for durability that the gentle-use population will never test. There is no single correct answer—but there is a correct process, which involves specifying the target use environment and selecting decoration methods accordingly.

The financial implications of decoration method durability mismatch extend beyond the initial order cost. When UV-printed logos begin degrading after six months, buyers face three unpalatable options: accept the brand liability of circulating products with faded logos, initiate a replacement program at full cost (since durability failures are not covered by supplier warranties when use environment was never specified), or attempt to negotiate with suppliers who correctly point out that the delivered products matched the approved samples and the buyer never specified durability requirements. Each option carries costs—financial, reputational, or relational—that could have been avoided through proper specification during the selection phase.

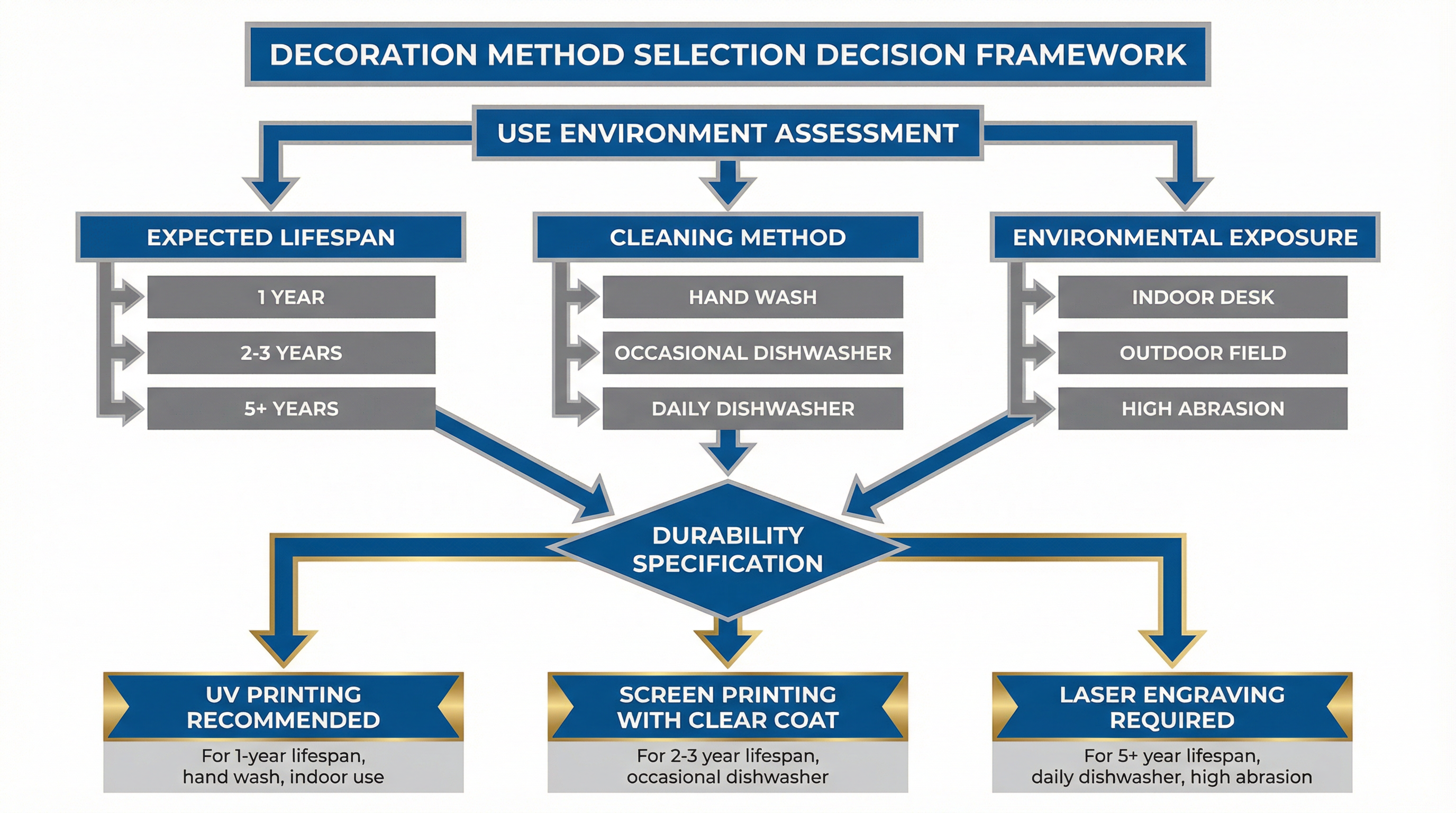

The solution is not to avoid UV printing or mandate laser engraving for all orders. The solution is to integrate use environment specification into the decoration method selection process. Before selecting a decoration method, buyers should define three parameters: expected product lifespan (one year for event giveaways, three to five years for employee programs, indefinite for executive gifts), anticipated cleaning frequency and method (hand-wash only, occasional dishwasher, daily dishwasher), and exposure conditions (indoor desk use, outdoor field use, high-abrasion environments like gym bags or tool kits). These parameters create a durability specification that guides decoration method selection toward appropriate options.

For products with one-year expected lifespan and gentle cleaning, UV printing delivers excellent visual impact at reasonable cost. For products with three-year expected lifespan and regular dishwasher exposure, laser engraving or high-durability screen printing (with protective clear coat) provides appropriate longevity. For products with indefinite expected lifespan or harsh environmental exposure, laser engraving is the only decoration method that guarantees permanent brand presentation. These are not value judgments about which method is "better"—they are engineering specifications that match decoration technology to use requirements.

The broader lesson for procurement teams navigating the custom drinkware customization workflow is that decoration method selection cannot be isolated from use environment specification. Suppliers will not volunteer durability limitations because doing so complicates sales conversations and may steer buyers toward lower-margin options. Buyers must proactively specify use environment requirements and request durability data (dishwasher cycle testing, abrasion resistance ratings, UV exposure stability) before committing to decoration methods. This specification discipline transforms decoration method selection from a subjective design preference into an objective durability engineering decision—and prevents the six-month logo degradation scenario that transforms brand assets into brand liabilities.

The practical implementation of use environment specification requires adding three questions to the decoration method evaluation process. First, what is the minimum acceptable appearance lifespan for this product, measured in years of intended use? Second, what cleaning method will recipients use, and how frequently? Third, what environmental exposures will the product encounter during normal use? These questions generate the durability specification that guides decoration method selection. A buyer who answers "three years, dishwasher twice weekly, indoor office use" has defined a durability requirement that eliminates standard UV printing from consideration unless the supplier can provide dishwasher cycle testing data demonstrating 300+ cycle durability. A buyer who answers "one year, hand-wash only, trade show giveaway" has defined a durability requirement that makes UV printing entirely appropriate despite its lower long-term durability.

The decoration method durability mismatch is not a supplier quality issue or a manufacturing defect. It is a specification gap that buyers create when they treat decoration method selection as a visual preference rather than a durability engineering decision. Closing this gap requires procurement teams to define use environment requirements before evaluating decoration options, request durability testing data from suppliers, and select decoration methods based on the intersection of visual requirements and durability specifications. This process discipline prevents the predictable disappointment of discovering that beautiful UV-printed logos fade after six months of the heavy use that buyers failed to specify during the selection phase.

The distinction between design decisions and durability specifications is subtle but consequential. A design decision asks: which decoration method makes our logo look best? A durability specification asks: which decoration method will maintain acceptable brand presentation throughout the product's intended lifespan in its intended use environment? Buyers who ask only the first question receive answers that satisfy visual requirements while leaving durability outcomes to chance. Buyers who ask both questions receive answers that satisfy visual requirements within durability constraints—and avoid the six-month degradation scenario that transforms custom drinkware from a brand investment into a brand liability.