When buyers select a domestic supplier specifically to shorten lead time, they operate under an assumption that feels self-evident: a supplier based in the United States will deliver faster than a supplier based overseas. This assumption is rooted in geographic proximity and the elimination of transoceanic shipping, customs clearance, and the logistical complexity of international freight. For many product categories, this assumption holds true. However, in the custom drinkware industry, where stainless steel tumblers, ceramic mugs, and insulated bottles rely on specialized components—stainless steel blanks, silicone gaskets, powder coating materials, vacuum-sealed lids—the distinction between a supplier's assembly location and the origin of its components creates a lead time blind spot that consistently undermines buyer expectations.

Figure 1: Direct import vs domestic assembly timeline comparison showing the hidden component procurement phase

Figure 1: Direct import vs domestic assembly timeline comparison showing the hidden component procurement phase

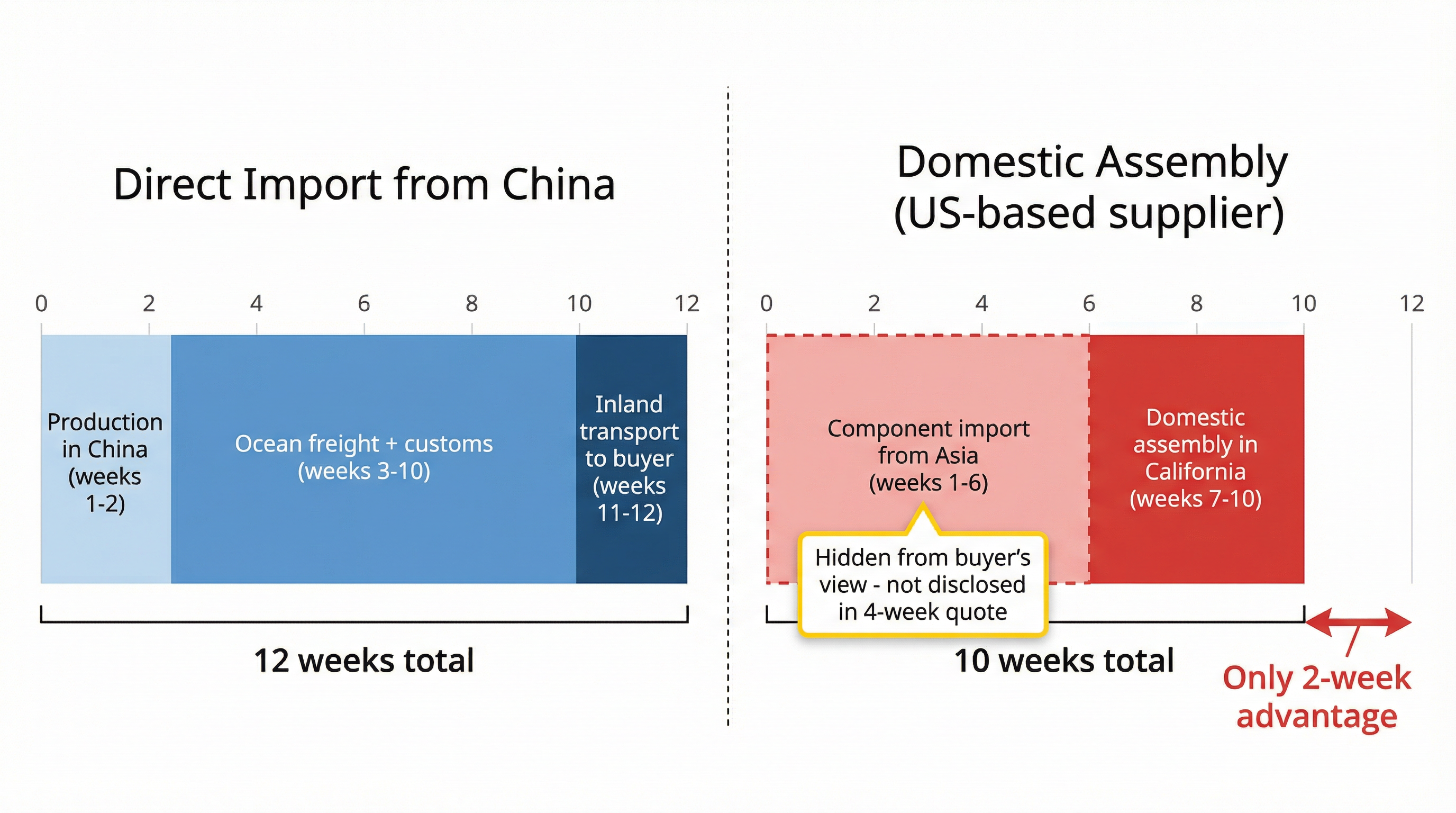

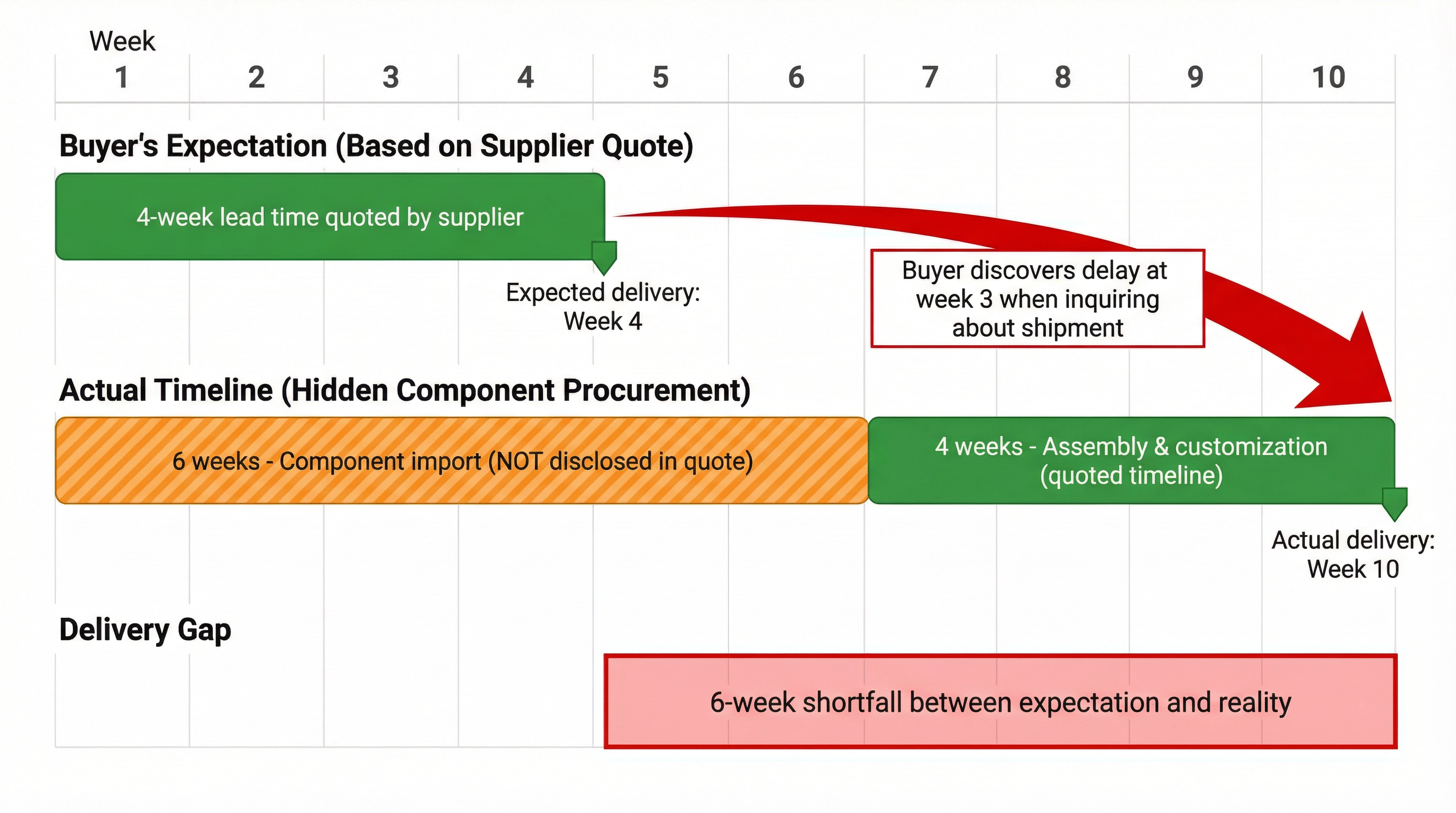

The misjudgment begins during the RFQ phase. A buyer soliciting quotes for 2,000 custom stainless steel tumblers receives proposals from multiple suppliers. Supplier A, based in Guangdong, China, quotes a twelve-week lead time, FOB Shanghai. Supplier B, based in California, quotes a four-week lead time, DDP to the buyer's warehouse in Ohio. The buyer, operating under time pressure to meet a corporate event deadline, selects Supplier B, reasoning that the eight-week lead time advantage justifies the higher unit cost. The buyer's internal planning spreadsheet reflects a four-week timeline, and the procurement team schedules downstream activities—distribution, packaging, event logistics—based on this assumption.

What the buyer does not recognize, and what the supplier's quote does not disclose, is that Supplier B's four-week lead time refers exclusively to the domestic assembly and customization phase. The supplier operates a facility in California where stainless steel blanks are laser-engraved, powder-coated, and assembled with lids and gaskets. However, the supplier does not manufacture the stainless steel blanks, the silicone gaskets, or the powder coating materials. These components are sourced from Asia, primarily China and Taiwan, and the supplier maintains a rolling inventory of these materials to support its domestic assembly operations. When the buyer places an order, the supplier's existing inventory is insufficient to fulfill the 2,000-unit order, requiring the supplier to place a component procurement order with its overseas suppliers. The component procurement timeline—ocean freight from Shanghai to Los Angeles, customs clearance, inland trucking to the California facility—adds six weeks to the total timeline. The actual delivery date becomes ten weeks from order placement, not four weeks.

Figure 2: Gap between quoted lead time and actual delivery timeline due to undisclosed component procurement

Figure 2: Gap between quoted lead time and actual delivery timeline due to undisclosed component procurement

The buyer discovers this discrepancy only when, at the three-week mark, the buyer inquires about shipment tracking and the supplier responds that production has not yet commenced because components are still in transit. The buyer's event is now seven weeks away, and the anticipated four-week buffer has collapsed into a one-week window. The buyer must either compress downstream logistics, incur expedited shipping costs, or accept that the tumblers will arrive too late for pre-event distribution. The buyer's decision to select a domestic supplier specifically to shorten lead time has resulted in only a two-week advantage over direct import from China—a marginal improvement that does not justify the premium pricing the domestic supplier commanded.

This scenario is not an anomaly. It reflects a structural characteristic of the U.S. custom drinkware supply chain, where domestic suppliers frequently operate as assembly and customization facilities rather than vertically integrated manufacturers. The components that define the functionality of a stainless steel tumbler—the double-wall vacuum insulation, the food-grade stainless steel, the leak-proof silicone gasket—are manufactured in regions with specialized production capacity, primarily East Asia. A domestic supplier that advertises "Made in USA" or "Assembled in USA" is making a statement about where final assembly occurs, not about where the components originate. The Federal Trade Commission's "all or virtually all" standard for "Made in USA" claims requires that most of a product's cost and processing be domestic, but many domestic drinkware suppliers qualify their claims as "Assembled in USA with foreign components" or "Made in USA with globally sourced materials." These qualifications are legally accurate, but they do not convey the lead time implications of component sourcing to buyers who are focused on delivery timelines rather than labeling compliance.

The lead time blind spot is compounded by the way suppliers structure their quotes. When a domestic supplier quotes a four-week lead time, the supplier is typically quoting the time required to complete the assembly and customization process once components are available. The supplier assumes that its existing component inventory will cover the order, or that the buyer understands that component procurement is a separate timeline. Buyers, however, interpret the four-week quote as the total time from order placement to delivery, because that is the information they need to plan around. The supplier's quote does not include a line item for "component procurement lead time," and the buyer does not ask whether the supplier's lead time includes component sourcing, because the buyer assumes that a domestic supplier has domestic components readily available.

In production planning, this is where lead time calculations start to break down. From a manufacturing standpoint, the distinction between assembly lead time and component procurement lead time is critical. A factory that operates on a just-in-time inventory model can quote short assembly lead times because it assumes components will arrive on schedule. However, when component suppliers face their own capacity constraints, shipping delays, or customs backlogs, the assembly facility's lead time quote becomes meaningless. The buyer, who selected the domestic supplier to avoid the risks of international logistics, discovers that the domestic supplier's supply chain is equally exposed to those risks, but the exposure is hidden one tier upstream in the component procurement phase.

The consequences of this blind spot extend beyond individual orders. Buyers who experience repeated delivery shortfalls from domestic suppliers begin to question whether domestic sourcing offers any meaningful lead time advantage. Some buyers revert to direct import from overseas suppliers, reasoning that if the total timeline is ten weeks regardless of supplier location, they might as well select the supplier with the lowest unit cost. Other buyers build informal buffers into their planning, ordering six weeks earlier than necessary to account for the hidden component procurement timeline. These adaptive behaviors impose inefficiencies across the supply chain. Buyers who order six weeks early tie up working capital in inventory that sits idle. Domestic suppliers lose business to overseas competitors because buyers perceive them as unreliable, when in reality the domestic suppliers' lead time quotes were accurate for the assembly phase but incomplete for the total procurement cycle.

The structural solution to this blind spot would be for domestic suppliers to provide stage-based lead time quotes that separate component procurement from assembly. A quote that specifies "six weeks for component procurement, four weeks for assembly and customization, total timeline ten weeks" would allow buyers to make informed comparisons between domestic and overseas suppliers. However, suppliers resist this level of transparency because it exposes the fact that their lead time advantage over direct import is marginal. A domestic supplier that quotes a ten-week total timeline competes directly with an overseas supplier that quotes a twelve-week timeline, and the two-week difference may not justify the domestic supplier's premium pricing. By quoting only the assembly phase, the domestic supplier creates the impression of a significant lead time advantage, even though the total timeline is comparable.

For buyers, the practical implication is that "domestic supplier" should not be treated as synonymous with "domestic timeline" without verification. During the RFQ phase, buyers should ask suppliers to clarify whether their lead time quote includes component procurement, and what percentage of components are sourced domestically versus internationally. A supplier that sources 70% of components from Asia should not be expected to deliver on a domestic timeline, regardless of where its assembly facility is located. Buyers should also request stage-based timelines that break down component procurement, production, and delivery into separate phases, allowing the buyer to identify where delays are most likely to occur and whether the supplier's total timeline aligns with the buyer's deadline.

Understanding how production timelines are structured requires recognizing that lead time is not determined solely by the location of the final assembly facility, but by the origin and procurement timeline of every component that contributes to the finished product. A domestic supplier that assembles tumblers in California but sources stainless steel blanks from Shanghai operates on a hybrid timeline that combines domestic assembly speed with international component procurement delays. Buyers who fail to account for this hybrid structure will consistently miscalculate delivery dates, not because the supplier is unreliable, but because the buyer's lead time assumptions do not align with the supplier's supply chain reality.

The domestic sourcing lead time blind spot is particularly problematic for buyers who are under time pressure and willing to pay a premium for faster delivery. These buyers select domestic suppliers specifically to avoid the risks of international logistics, only to discover that the domestic supplier's supply chain is equally dependent on international component flows. The premium pricing the buyer pays for domestic assembly does not translate into a proportional lead time reduction, because the majority of the timeline is determined by component procurement, not assembly. A buyer who pays 20% more for a domestic supplier expecting an eight-week lead time reduction receives only a two-week reduction, resulting in a cost-per-week-saved that is four times higher than anticipated.

The challenge for buyers is that component origin information is rarely disclosed upfront. Suppliers assume that their assembly location is the relevant information for lead time planning, and buyers assume that a domestic assembly location implies a domestic supply chain. Neither party recognizes the misalignment until a delivery date approaches and the buyer inquires about shipment status, only to discover that components are still in transit from overseas. By that point, the buyer's options are limited—accept the delayed delivery, pay for expedited shipping, or cancel the order and source from an alternative supplier, which resets the timeline entirely.

In the context of total lead time planning, the distinction between assembly location and component origin is not a technical detail; it is the primary determinant of whether a domestic supplier can deliver on a domestic timeline. Buyers who treat "Assembled in USA" as a proxy for "fast delivery" will continue to encounter delivery shortfalls that disrupt their operations. Those who approach domestic sourcing with the understanding that assembly location and component origin are separate variables, and who verify component procurement timelines during the RFQ phase, will find that their suppliers deliver more consistently to expectations—not because the suppliers have become faster, but because the buyer's expectations were aligned with the supplier's actual supply chain structure from the outset.