There is a particular category of customization dispute that surfaces with predictable regularity in corporate drinkware procurement, and it almost always follows the same pattern. A buyer specifies logo dimensions based on the maximum imprint area listed in a supplier's product specification sheet. The artwork is prepared to fill that maximum space. The digital proof is approved. Production proceeds. And then the delivered product arrives with text that requires a magnifying glass to read, circular logos that appear as ovals, and fine details that have merged into illegible blobs. The buyer insists the supplier failed to execute the approved design. The supplier insists the delivered product matches the approved proof exactly. Both parties are technically correct, which is precisely why this dispute is so difficult to resolve.

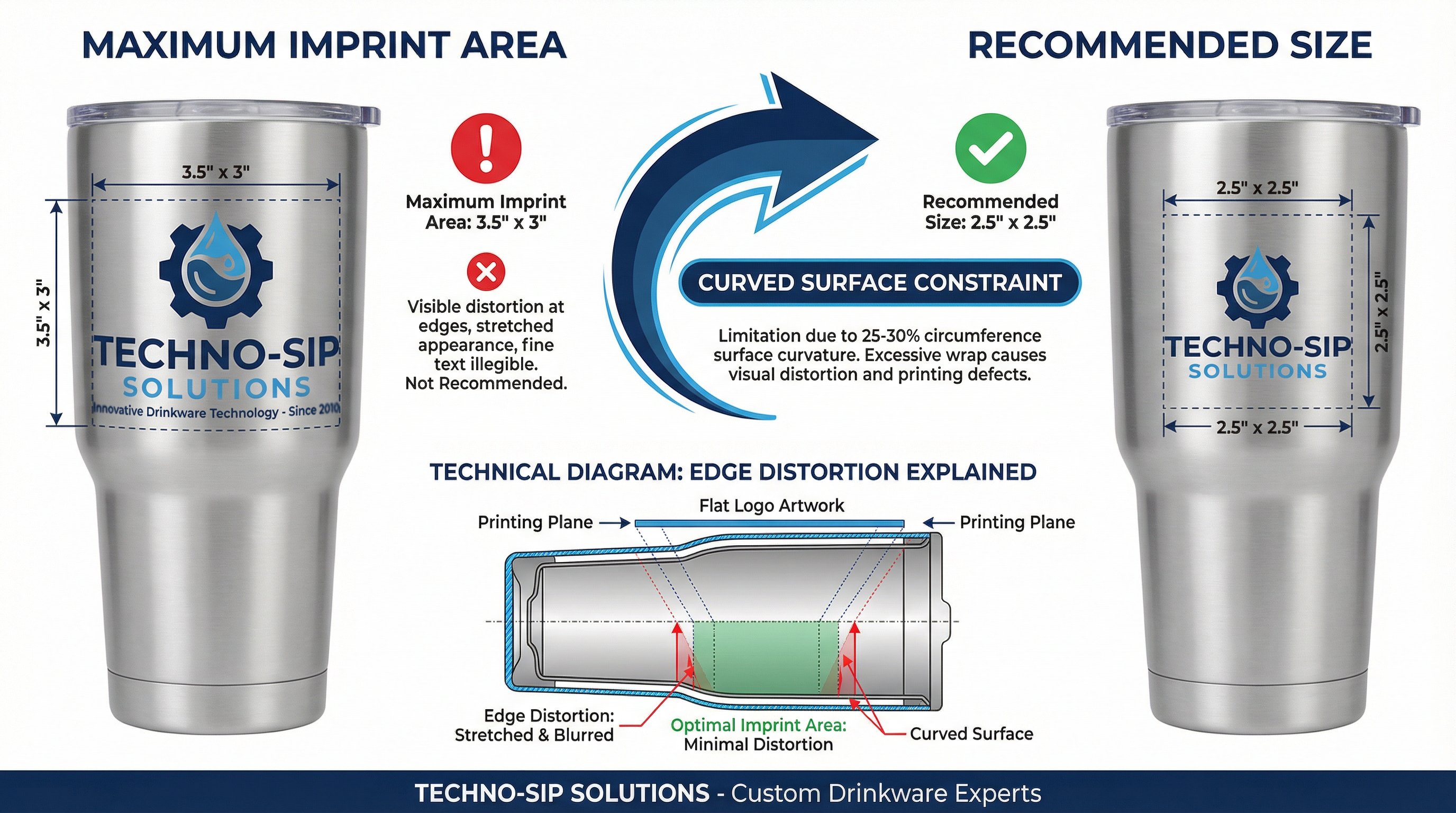

The root cause is not supplier negligence or buyer carelessness. It is a fundamental misunderstanding of what "maximum imprint area" actually means in the context of cylindrical drinkware decoration. When a product specification states that a 20-ounce stainless steel tumbler has a maximum imprint area of 3.5 inches wide by 3 inches high, that figure represents the absolute physical boundary within which decoration equipment can operate. It does not represent the optimal size for legible, visually balanced branding. The distinction matters enormously, yet it is almost never explained during the quotation phase, and buyers who have never encountered this issue have no reason to question the numbers they receive.

The physics of printing on curved surfaces imposes constraints that flat artwork cannot anticipate. A cylindrical tumbler is not a flat canvas wrapped around a cylinder. When decoration equipment applies ink, laser energy, or screen-printed pigment to a curved surface, the substrate is rotating while the decoration head remains stationary. This rotational application means that the effective print width is limited to approximately 25-30% of the total circumference before image distortion becomes visually apparent. On a standard 20-ounce tumbler with a circumference of approximately 11 inches, this translates to a practical print width of 2.75-3.3 inches. The maximum imprint area specification of 3.5 inches represents the equipment's capability, not the quality threshold. Pushing to that maximum introduces stretching at the edges of the design, where the curved surface begins to rotate away from the optimal print angle.

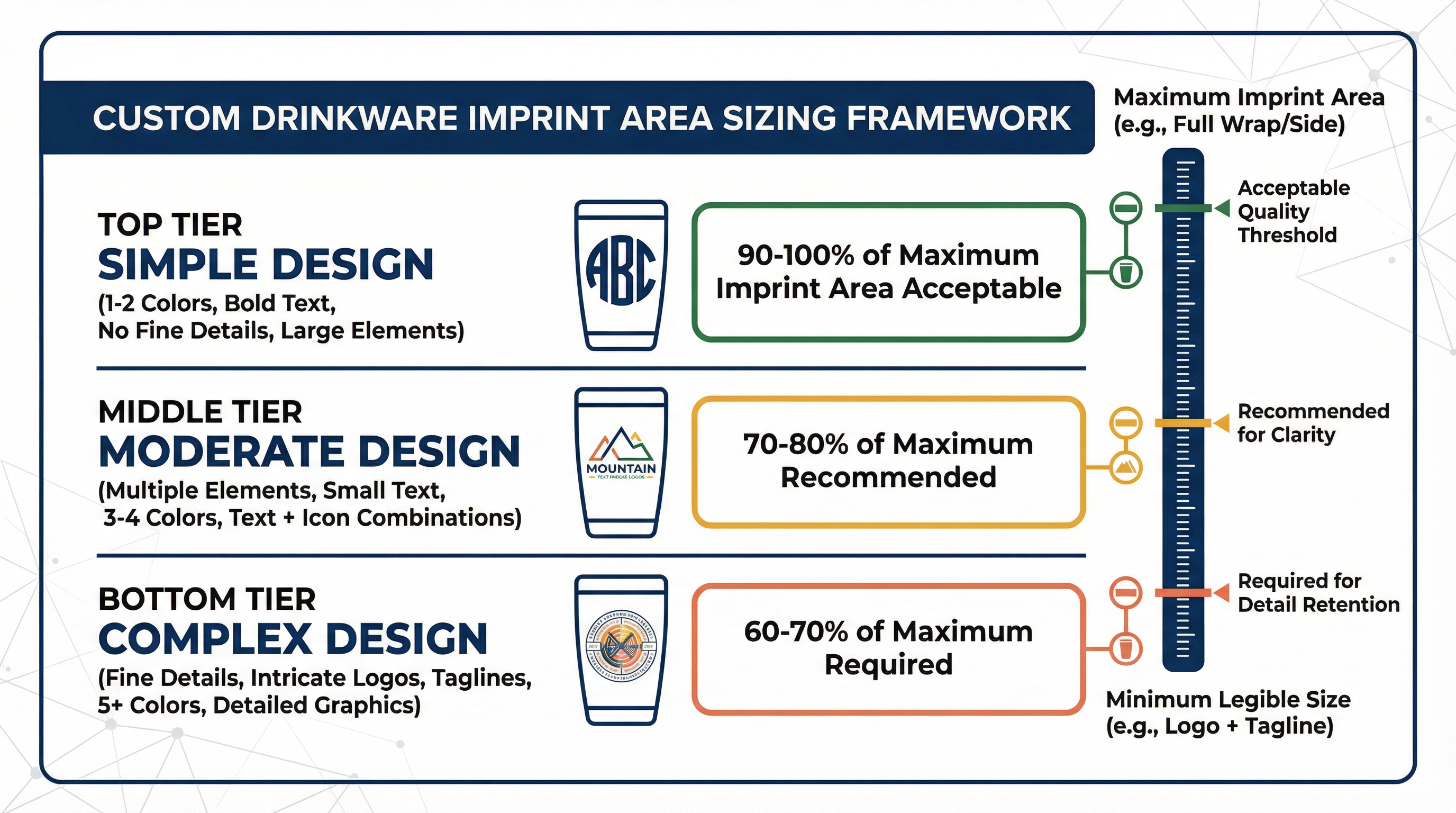

This becomes particularly problematic for logos containing fine text, thin lines, or intricate details. When a corporate logo includes a tagline in 8-point font, that text may be perfectly legible on a business card or website header. Scaled to fill a 3.5-inch imprint area on a curved tumbler, the same text occupies a physical space that appears significantly smaller to the human eye due to the curvature. The viewer's eye naturally follows the curve, and text at the edges of the imprint area appears foreshortened. What reads clearly on a flat digital proof becomes strained and uncomfortable on the physical product. The recommended imprint size—typically 20-30% smaller than the maximum—accounts for this perceptual compression by leaving margin space that prevents critical design elements from extending into the distortion zone.

The situation compounds when dealing with tapered tumblers, which represent the majority of modern insulated drinkware designs. A tapered tumbler is not a true cylinder but a truncated cone, with a larger diameter at the top and a smaller diameter at the bottom. When decoration equipment rotates a tapered tumbler, the surface speed at the top of the design differs from the surface speed at the bottom. If the decoration software treats the tumbler as a perfect cylinder—which most standard equipment does—the design will converge toward the narrower end. A perfectly square logo becomes a trapezoid. A circle becomes an oval. Horizontal text appears to curve downward at the edges. These distortions are mathematically predictable based on the taper angle and design height, but they are invisible on flat digital proofs and only become apparent on the physical product.

The correction for tapered surface distortion requires pre-distorting the artwork in the opposite direction, so that the decoration process produces a visually correct result. This pre-distortion calculation depends on the specific tumbler dimensions: the major diameter at the top, the minor diameter at the bottom, the vertical height of the tapered section, and the position of the artwork within that section. A logo placed near the top of a tapered tumbler requires less correction than the same logo placed near the bottom, where the diameter difference is more pronounced. Suppliers who specialize in high-volume corporate drinkware typically have this correction capability built into their production workflow. Suppliers who primarily serve the consumer personalization market may lack the technical sophistication to perform accurate taper correction, resulting in delivered products where geometric shapes appear skewed despite approved proofs showing perfect alignment.

The practical consequence of this physics is that buyers who specify maximum imprint area dimensions are essentially requesting that their supplier push decoration equipment to its operational limits. Some suppliers will comply without comment, producing technically correct but visually suboptimal results. Other suppliers will silently reduce the design size to recommended dimensions, producing better visual results but potentially triggering disputes when buyers measure the delivered product and discover the logo is smaller than specified. Neither approach serves the buyer's actual objective, which is presumably to receive drinkware with professional, legible branding that enhances rather than undermines corporate image.

Understanding the complete workflow for custom drinkware decoration requires recognizing that imprint area specifications exist within a hierarchy of constraints. The maximum figure represents equipment capability. The recommended figure represents quality optimization. The actual optimal size for any specific design depends on the design's complexity, the decoration method's resolution limits, and the intended viewing distance. A simple two-color logo with bold text can approach maximum dimensions without significant quality degradation. A complex multi-element design with fine details and small text should remain well within recommended dimensions to maintain legibility.

The resolution limits of different decoration methods further complicate sizing decisions. Laser engraving on stainless steel can reproduce line widths as fine as 0.3-0.5 millimeters, making it suitable for detailed designs at smaller sizes. UV printing typically requires minimum line widths of 0.8-1.0 millimeters to maintain edge definition, meaning the same design may need to be 50-100% larger to achieve equivalent legibility. Screen printing requires even wider minimum line widths of 1.5-2.0 millimeters due to ink spread characteristics. A buyer who specifies maximum imprint area without considering decoration method resolution may receive a product where the logo size is correct but the fine details have merged into unreadable masses.

The viewing distance assumption embedded in imprint area specifications also deserves scrutiny. Product specification sheets typically assume a viewing distance of 12-18 inches—the distance at which someone holding a tumbler would naturally view the branding. Corporate drinkware, however, often serves as ambient branding in conference rooms, office kitchens, or event spaces where viewing distances of 3-6 feet are common. At these distances, a logo sized for 18-inch viewing becomes a small, indistinct mark. Buyers who intend their drinkware to serve as visible branding in group settings should consider sizing their logos 20-40% larger than they would for personal-use items, which may require selecting larger drinkware products rather than maximizing imprint area on smaller products.

The financial implications of imprint area misjudgment extend beyond the immediate order. When delivered products fail to meet visual expectations, buyers face a difficult choice: accept suboptimal branding that will represent their company for the product's lifespan, or negotiate re-production at significant cost and delay. Re-production typically requires new artwork preparation with corrected sizing, new proof approval cycles, and expedited production to recover lost time. For a 2,000-unit corporate gifting program with a fixed event date, the re-production option may not exist—the buyer must distribute products they consider inadequate or cancel the program entirely. Neither outcome serves the original objective of enhancing corporate image through quality branded merchandise.

The specification process that prevents these outcomes requires a different approach than simply requesting maximum imprint area dimensions. Buyers should provide suppliers with the actual artwork file and request a recommendation for optimal sizing based on the specific design's complexity and the intended decoration method. This consultation shifts the sizing decision from the buyer—who lacks technical knowledge of decoration constraints—to the supplier—who understands their equipment's capabilities and limitations. Suppliers who resist providing sizing recommendations, or who simply confirm that maximum dimensions are achievable without discussing quality implications, are signaling either technical inexperience or indifference to outcome quality.

Physical sample approval becomes even more critical when imprint area sizing is uncertain. A digital proof cannot reveal how fine text will render on a curved surface, how geometric shapes will distort on a tapered tumbler, or how edge stretching will affect design elements near the imprint area boundary. Only a physical sample, viewed at actual size on the actual product, provides the information necessary to evaluate whether the specified sizing produces acceptable results. Buyers who skip physical sampling to save $100-200 in sample costs are gambling that their sizing specifications will produce satisfactory results—a gamble that fails with sufficient frequency to make sampling the economically rational choice.

The internal approval process for custom drinkware should include stakeholders who will evaluate the physical product, not just the digital proof. Marketing teams accustomed to reviewing artwork on 27-inch monitors may approve designs that appear inadequate when printed at actual size on a 3-inch-diameter tumbler. Executive sponsors who will ultimately distribute the drinkware should see physical samples before production approval, ensuring that the delivered product meets their expectations for brand representation. Consolidating this feedback during the sampling phase prevents the post-production disputes that arise when decision-makers first see the physical product after 2,000 units have been manufactured.

The recommended imprint area exists not as a conservative limitation but as a quality boundary established through extensive production experience. Suppliers who have decorated thousands of tumblers understand where design quality degrades on curved surfaces, where text becomes illegible, and where geometric distortion becomes visually objectionable. The 20-30% reduction from maximum to recommended dimensions represents accumulated knowledge about where these quality thresholds occur. Buyers who insist on maximum dimensions are essentially rejecting this expertise in favor of their own assumptions about what the equipment can achieve. Sometimes those assumptions prove correct. More often, they produce results that technically meet specifications while failing to meet expectations.