When procurement teams receive a digital proof from their drinkware supplier, the immediate instinct is to route it through the fastest approval path—typically an administrative coordinator or junior marketing associate who can confirm "yes, the logo looks right" and move the project forward. This delegation appears efficient on the surface, particularly when managing multiple concurrent orders across different product categories. The proof arrives via email, the designated approver opens it on their desktop monitor under the standard office fluorescent lighting, confirms the logo placement matches the brand guidelines, and replies with approval within an hour. Production begins, the order progresses through manufacturing, and eight weeks later the shipment arrives at the receiving dock. That's when the phone calls start.

The receiving manager unpacks a sample tumbler, walks it outside to inspect under natural daylight, and immediately notices the navy blue logo appears significantly darker than the approved brand color. The marketing director pulls the tumbler into the conference room under LED downlights and observes the same issue—the color reads as almost black rather than the specified Pantone 289C. The procurement team pulls up the approved digital proof, which still displays the logo as a vibrant navy blue on their backlit monitor, and begins the uncomfortable process of explaining to leadership why 2,000 custom tumblers don't match the brand despite having an approved proof in the project file. This scenario repeats itself across corporate procurement departments with enough regularity that it reveals a fundamental misjudgment in how proof approval authority is assigned and executed.

The core issue is not that the administrative staff member lacks diligence or attention to detail. The problem is that proof approval for custom drinkware is not an administrative task—it is a technical validation milestone that requires cross-functional input from brand management (who understand color tolerance ranges and substrate behavior), procurement (who understand supplier capability and contract terms), and receiving personnel (who will physically inspect the delivered product under the actual lighting conditions where it will be used or distributed). When approval authority is delegated to a single individual without technical color matching knowledge, the organization creates a situation where production commitment is made based on incomplete evaluation. The approved proof becomes a legal document that locks in the supplier's obligation to match what was shown, but if what was shown does not accurately represent how the physical product will appear under real-world lighting conditions, the approval itself becomes the source of the problem rather than the solution.

This misjudgment typically originates from a well-intentioned efficiency optimization. Procurement teams operate under constant pressure to reduce approval cycle times, particularly when managing seasonal campaigns or event-driven orders with fixed delivery deadlines. Routing a proof through three or four stakeholders for cross-functional review adds 2-3 days to the approval timeline, and when the digital mockup "looks fine" on a computer screen, the additional review appears unnecessary. The administrative coordinator has access to the brand guidelines PDF, can confirm the logo file matches the approved version, and can verify the placement follows the supplier's template. From a process efficiency standpoint, delegating approval to this individual makes perfect sense—until the physical product arrives and reveals that digital mockup approval under office fluorescent lighting does not predict physical product acceptance under natural daylight, LED lighting, or the mixed lighting conditions present in corporate lobbies, conference rooms, or outdoor events where the drinkware will actually be used.

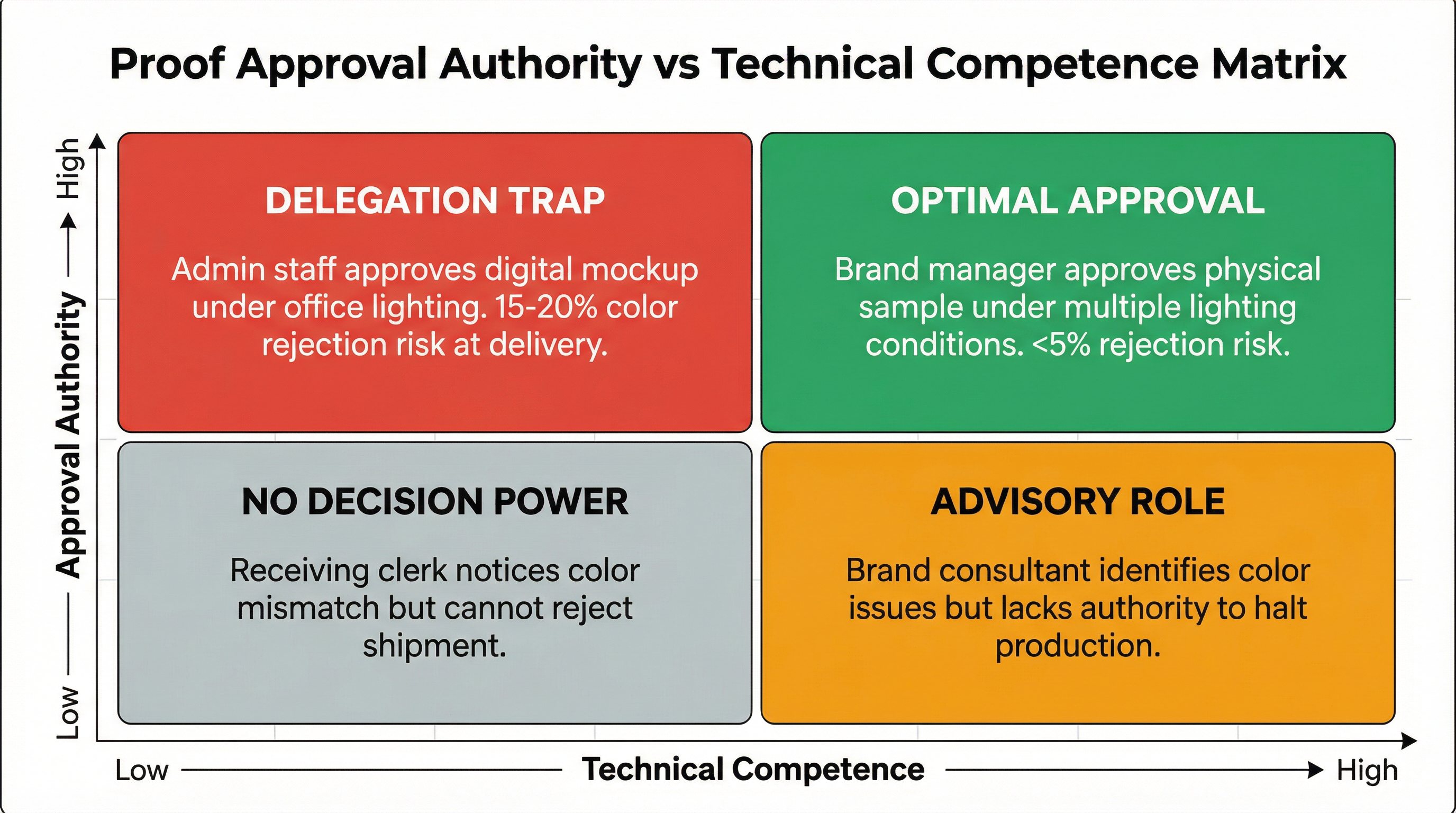

Figure 1: Proof Approval Authority vs Technical Competence Matrix showing the delegation trap (top-left quadrant) where high approval authority combined with low technical competence creates 15-20% color rejection risk at delivery.

Figure 1: Proof Approval Authority vs Technical Competence Matrix showing the delegation trap (top-left quadrant) where high approval authority combined with low technical competence creates 15-20% color rejection risk at delivery.

The technical reality that creates this trap is that color perception is not absolute—it is contextual and depends on the light source illuminating the object, the reflectance properties of the substrate, and the observer's visual adaptation to the surrounding environment. A digital mockup displayed on a backlit LCD monitor emits light directly into the viewer's eye, with the color rendered through RGB (red, green, blue) additive color mixing. The same logo printed on a powder-coated stainless steel tumbler reflects ambient light from the surrounding environment, with the color rendered through CMYK (cyan, magenta, yellow, black) subtractive color mixing or Pantone spot color ink formulations. These are fundamentally different color reproduction systems, and they do not produce identical visual results even when the color specifications are technically matched. A Pantone 289C navy blue logo that appears vibrant and saturated on a backlit screen may appear 15-20% darker on a matte powder-coated surface under natural daylight because the substrate absorbs more light and reflects less back to the viewer's eye.

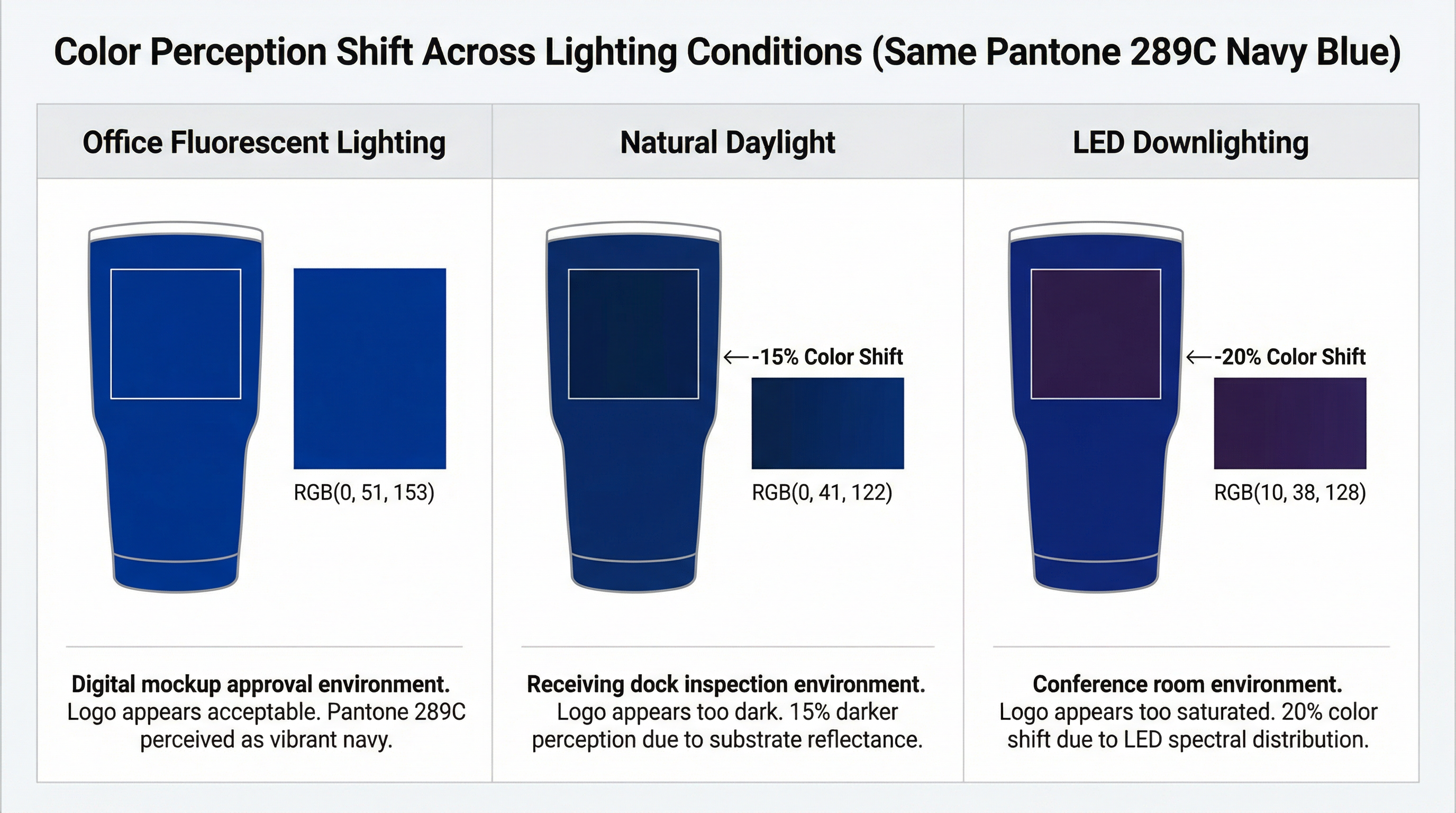

Figure 2: Color Perception Shift Across Lighting Conditions showing the same Pantone 289C navy blue logo appearing 15-20% darker under natural daylight and LED downlighting compared to office fluorescent lighting where digital mockup approval typically occurs.

Figure 2: Color Perception Shift Across Lighting Conditions showing the same Pantone 289C navy blue logo appearing 15-20% darker under natural daylight and LED downlighting compared to office fluorescent lighting where digital mockup approval typically occurs.

Office fluorescent lighting compounds this problem because it has a different spectral distribution than natural daylight or LED lighting. Fluorescent tubes emit light with strong peaks in the blue and green wavelengths and weaker output in the red wavelengths, which shifts color perception toward cooler tones. A navy blue logo that appears acceptable under fluorescent lighting may appear too dark or too saturated under natural daylight (which has a more balanced spectral distribution across all visible wavelengths) or under warm LED lighting (which has stronger output in the red and amber wavelengths). When an administrative staff member approves a digital proof while viewing it on a backlit monitor under fluorescent office lighting, they are making a color judgment under conditions that do not represent how the physical product will be perceived by the end recipient. The approval is technically valid—the digital mockup does show Pantone 289C—but it does not predict whether the physical product will be visually acceptable under the lighting conditions where it will actually be used.

The delegation trap is further reinforced by the fact that administrative staff typically lack the authority or technical knowledge to negotiate color tolerance ranges with the supplier. Understanding the complete customization workflow requires recognizing that proof approval is not a binary yes/no decision—it is a negotiation of acceptable variation ranges. Professional brand managers understand that achieving an exact Pantone match on powder-coated steel is technically challenging due to substrate texture, coating thickness variations, and curing temperature differences across production batches. They know to specify a +/- 10% color tolerance in the supplier contract and to request physical samples under multiple lighting conditions before approving production. Administrative staff, operating without this technical context, treat proof approval as a simple confirmation that "the logo looks right" without understanding that "looks right under office fluorescent lighting on a backlit screen" is not the same as "will be acceptable under natural daylight on a matte powder-coated surface." The approval is given with good intentions, but it commits the organization to a production outcome that may not meet stakeholder expectations at delivery.

The consequences of this misjudgment extend beyond the immediate color rejection issue. When the receiving manager rejects the shipment due to color mismatch, the procurement team must navigate a dispute resolution process with the supplier. The supplier will reference the approved digital proof, which technically shows the specified Pantone color, and argue that they fulfilled their contractual obligation to match what was approved. The procurement team will argue that the physical product does not match the brand's visual expectations, but without a physical sample approval or documented color tolerance negotiation in the contract, they have limited leverage to demand a reorder at the supplier's expense. The dispute often results in a compromise where the buyer accepts a partial credit (10-15% of the order value) and uses the non-conforming inventory for lower-visibility applications, but the brand impact and internal stakeholder frustration remain. The original efficiency gain from fast-tracking the proof approval is erased by the 2-3 weeks spent negotiating the dispute and the reputational cost of distributing drinkware that does not meet brand standards.

The misjudgment also creates a precedent problem within the procurement organization. Once administrative staff are established as the default proof approvers, it becomes organizationally difficult to reintroduce cross-functional review without implying that previous approvals were inadequate. The administrative coordinator who approved the problematic proof may feel unfairly blamed for a technical issue they were not equipped to identify, and brand managers may resist being pulled into future proof reviews because "we already have an approval process in place." The efficiency optimization that seemed reasonable at the time becomes embedded in the organization's workflow, and subsequent orders continue to follow the same pattern—digital mockup approval under office lighting by non-technical staff, production commitment without physical sample validation, and periodic color rejection issues that are treated as isolated supplier failures rather than systemic process failures.

Breaking out of this trap requires redefining proof approval as a technical validation milestone rather than an administrative checkbox. The first step is establishing a cross-functional approval protocol that requires sign-off from brand management, procurement, and receiving before production commitment. Brand management reviews the digital mockup for color accuracy, logo placement, and compliance with brand guidelines, but they also specify the acceptable color tolerance range and request a physical sample for validation under multiple lighting conditions. Procurement reviews the supplier's contract terms to confirm that the tolerance range is documented and that dispute resolution procedures are clearly defined. Receiving personnel review the physical sample under the actual lighting conditions where the delivered product will be inspected—natural daylight, LED downlights, or mixed lighting—and confirm that the color appearance is acceptable under those conditions. This cross-functional review adds 2-3 days to the approval timeline, but it prevents the 2-3 week dispute resolution process and the reputational cost of distributing non-conforming inventory.

The second step is requiring physical sample approval for any order where color accuracy is critical to brand perception. Digital mockups are useful for confirming logo placement, text legibility, and overall design layout, but they are not reliable predictors of physical product color appearance under real-world lighting conditions. Suppliers can provide physical samples (typically 1-3 units) within 7-10 days after digital mockup approval, and these samples should be evaluated under natural daylight, LED lighting, and fluorescent lighting to confirm that the color appearance is acceptable across all conditions. If the physical sample reveals a 15-20% color shift that makes the logo appear too dark or too saturated, the buyer can request a color adjustment before committing to full production. This adds 10-14 days to the overall lead time, but it eliminates the risk of receiving 2,000 tumblers that do not meet brand standards and the associated dispute resolution costs.

The third step is documenting the approval authority and technical competence requirements in the procurement organization's standard operating procedures. Proof approval for custom drinkware should be assigned to individuals who have technical color matching knowledge, access to brand guidelines with specified Pantone codes and tolerance ranges, and authority to negotiate contract terms with suppliers. Administrative staff can continue to manage the logistical coordination of proof requests and approval routing, but the final approval decision should rest with brand management or a designated technical reviewer who understands substrate reflectance behavior and lighting condition impacts on color perception. This clarification prevents the delegation trap from recurring and ensures that production commitment is made based on adequate technical evaluation.

The underlying lesson is that efficiency optimizations in procurement workflows must account for the technical complexity of the deliverable. Delegating proof approval to administrative staff works well for low-complexity items where visual appearance is not critical—generic promotional items, internal-use supplies, or commodity products where brand consistency is not a primary concern. For custom drinkware intended for client gifting, employee recognition, or event distribution, where brand perception and color accuracy directly impact the organization's reputation, proof approval is a technical validation milestone that requires cross-functional input and physical sample evaluation. The 2-3 days added to the approval timeline are not wasted time—they are an investment in preventing the 2-3 week dispute resolution process and the reputational cost of distributing non-conforming inventory. Organizations that treat proof approval as an administrative checkbox rather than a technical validation milestone consistently encounter color rejection issues at delivery, despite having approved proofs in their project files. Organizations that require cross-functional review and physical sample approval before production commitment achieve on-time delivery with acceptable color accuracy at predictable costs, because they validate the supplier's capability to meet brand standards before making a production commitment that is difficult to reverse.